- Metrology - Laboratory

- Analytical Instrumentation

- Metal analyzer

- Evident - Olympus Scientific Solutions

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

XRF analyzer Vanta™ iXmetalfor metallurgyelemental

Add to favorites

Compare this product

Characteristics

- Measured entity

- metal

- Application domain

- for metallurgy

- Measured value

- elemental

- Configuration

- in-line

- Mode of use

- automated

- Technology

- X-ray fluorescence, XRF

- Protection level

- IP54

- Other characteristics

- continuous, real-time, inspection

Description

Vanta™ iX In-Line XRF Analyzer for Automated Material Analysis

Keep Your Process Up to Speed

The Olympus Vanta™ iX in-line X-ray fluorescence (XRF) analyzer gives you confidence in your products by automating material analysis and alloy identification on the manufacturing line:

• Delivers instant results for real-time process monitoring and 100% inspection

• Built to operate 24/7

• Configured to deliver pass/fail results, accurate grade ID, and material chemistry

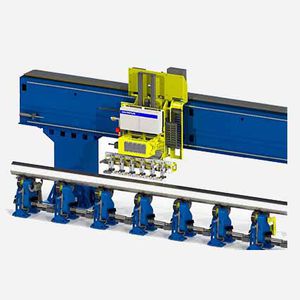

100% Inspection for Metal Fabrication of Tubes, Bars, and Rods

For organizations adopting Industry 4.0 practices and 24/7 process control to verify alloys with pass/fail analysis, the Vanta iX analyzer delivers material verification and lot/heat control for bar, billet, tube, and rod manufacturing, as well as machined parts and customized components. Automating your testing with a Vanta iX analyzer adds a competitive edge to your finished product since you can demonstrate that materials are 100% tested and verified.

Scanning and Monitoring for Ore Grade Control in Mining

For geological processing and mining, the Vanta iX analyzer enables core scanning and on-belt analysis with real-time results to monitor process variability and ensure ore grade consistency. During on-belt analysis, the analyzer provides blending verification and process validation of concentrates.

Fast and Accurate Elemental Analysis for Continuous Quality Control

Like all Vanta electronics, the Vanta iX analyzer works fast while delivering reliable, actionable results to guide critical decisions.

• High resolution: ID a range of alloy grades—including light and heavy elements

Catalogs

Other Evident - Olympus Scientific Solutions products

Bar Inspection Solutions

Related Searches

- Concentration analyser

- Desktop analyzer

- Automated analyzer

- Evident Olympus solids analyzer

- Portable analyser

- Continuous analyser

- Real-time analyser

- Laboratory analyser

- Calibration analyser

- In-line analyser

- Waterproof analyzer

- Quality control analyser

- Cost-effective analyzer

- Rugged analyser

- Evident Olympus elemental analyzer

- Evident Olympus stainless steel probe

- Heavy-duty analyzer

- Manual analyzer

- Environmental assessment analyzer

- Evident Olympus current probe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.