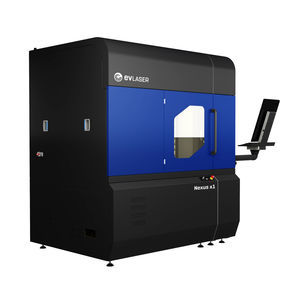

Fiber laser marking and engraving machine HEXAGONCO2 laserNd:YAG lasermetal

Add to favorites

Compare this product

Characteristics

- Technique

- fiber laser, CO2 laser, Nd:YAG laser

- Material

- metal, plastic

- Other characteristics

- automatic, computer-controlled, vision system

- Power

Min.: 3 kW

(4.08 hp)Max.: 500 kW

(679.81 hp)- X travel

300 mm

(11.81 in)- Y travel

300 mm

(11.81 in)

Description

Designed for Laser Marking and Engraving of processes with wide autonomy without operator, HEXAGON manages an integrated pallet warehouse that makes it autonomous for many hours of work. The number of trays (pallets) in the warehouse ranges from 15 in the standard version to 30 in the MAXI. The artificial vision system manages the marking of the pieces on trays by identifying, centering and rotating the machining on the pieces, avoiding the use of templates and eliminating the operator's workpiece positioning times.

Furthermore, the possibility of integrating HEXAGON with an anthropomorphic robot allows the marking of complex parts on several sides without the need for shooting.

All customer materials are workable with HEXAGON thanks to the integration of various LASER sources.

The system is equipped with the characteristics necessary to fall into the category of functional goods for the technological and digital transformation of companies according to the industry 4.0 model.

1.

AUTONOMY AND FLEXIBILITY

The ability to work independently without the intervention of the operator is the peculiarity of this system, which is also able to process different batches independently for several hours of processing. The possibility to choose between the version with 15 and 30 loading trays (pallets), allows the machine to be adapted to the needs of the individual customer.

2.

MOTION AND ROBOT

The system provides for the use of up to 3 XYZ axes for the processing phase and an axis for picking up and depositing pallets from the automatic warehouse. An anthropomorphic robot can be integrated as an option for multi-side or particularly complex machining.

Catalogs

No catalogs are available for this product.

See all of Evlaser srl‘s catalogsRelated Searches

- Marking and engraving system

- Laser marking and engraving system

- Fiber laser marking and engraving system

- Metal marking and engraving system

- CO2 laser marking and engraving system

- Industrial marking and engraving system

- Plastics marking and engraving system

- Automatic marking and engraving system

- Compact marking and engraving system

- Computer-controlled marking and engraving machine

- Vision system marking and engraving machine

- Digital marking and engraving machine

- Traceability marking and engraving machine

- Barcode marking and engraving machine

- Marking and engraving machine with rotary table

- OEM marking and engraving machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.