- Hydraulics - Pneumatics

- Valve

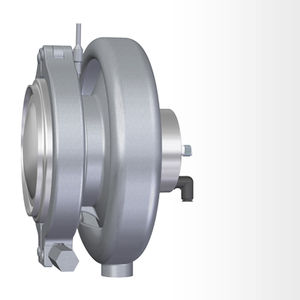

- Plug valve

- Evoguard GmbH

Pressure-control valve Oplugpneumaticfor water

Add to favorites

Compare this product

Characteristics

- Type

- plug

- Operation

- pneumatic

- Function

- pressure-control

- Media

- for water, for liquid food products and beverages

- Body

- seat, weld

- Applications

- for pipe, hygienic

Description

maintain a constant product pressure inside the pipes.

- Actuator allocation with adjustment to product pressure

- External air connection as a standard to open the valve during cleaning

- Internal air flow with the use of a control head to open the valve during cleaning

- Support for proximity switch mountable on the actuator

- Optimum design of fluid flow for pressure increase in the area of the valve seat

- Air connection for compressed-air superimposition

- Metal stop of the valve disk for sealing protection

- Two-part valve disk, screwed, with a defined space for the sealing ring for easy installation

screwed with lock against rotation

Resistance to rip-put and fluid behind the seal

- Shaft seal design:

Stripping function protects against contamination ingress

Geometry protects against being torn out

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.