Log saw ArcoLinebandwood

Add to favorites

Compare this product

Characteristics

- Technology

- band

- Treated material

- wood

- Applications

- log

Description

Resaw systems ArcoChipping + ArcoBand resaw + Edger optimizer for value, grade and recovery optimization of all possible sawing patterns

Important for the economic production of lumber is the maximization of recovery with the highest possible productivity and the highest possible sawing accuracy. Modern 3D scanning technology and complex optimization algorithms allow us to compute the highest possible recovery. The resaw process ArcoLine was developed for perfectly controlled execution of the results of the scanning and optimization process.

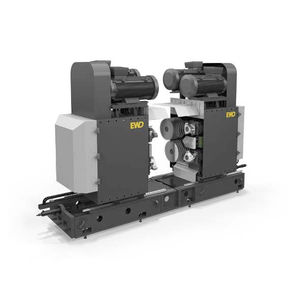

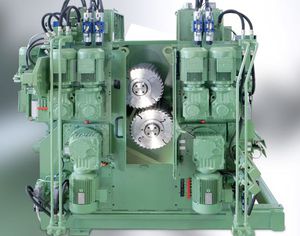

For the systems ArcoChipping + ArcoBand resaw+Edger optimizer the following machines are available for the active controlled curve chipping and curve sawing: Chipper canter model FZ 5 Arco and band resaw models EBT 1200 - 1800. The main component of the Arco-Technology is the chipper canter Arco FZ5.

The arco curve radius calculated by the optimization computer is followed by the chipper canter heads with a simultaneous linear movement of the heads and a pivot movement of the canter. During the chipping process, the cant is held on the in- and outfeed chain bed with no sideways movement. The command values of scanning and optimization can be executed along the length of the cant with millimeter accuracy.

Catalogs

No catalogs are available for this product.

See all of EWD‘s catalogsRelated Searches

- Cutting system

- Knife cutting system

- High-precision cutting system

- Automatic sawing machine

- Circular sawing machine

- Band sawing machine

- Wood sawing machine

- Rotary blade cut-off machine

- Precision sawing machine

- Wood cutting system

- Electric sawing machine

- Hydraulic sawing machine

- Compact sawing machine

- Variable-speed sawing machine

- High-speed sawing machine

- Profiling cutting machine

- Servo-driven cutting system

- Vertical cut-off machine

- Heavy-duty sawing machine

- Frame sawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.