- Machine-tools

- Machine Tool Accessory

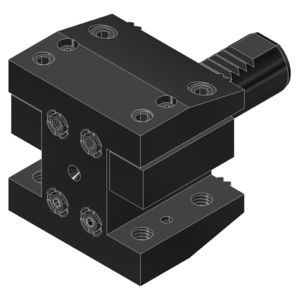

- VDI tool holder

- EWS Weigele GmbH & Co. KG

VDI tool holder 60.25VX3KRABCRLIKDI2V Weldoncolletmilling

Add to favorites

Compare this product

Characteristics

- Machine mount

- VDI

- Clamping method

- collet, Weldon

- Application

- for machining, milling

- Other characteristics

- quick-change, modular, radial, hydraulic

- Clamping range

70 mm

(2.76 in)- Rotational speed

6,000 rpm

(37,699 rad.min-1)

Description

With the patented quick-change system EWS.Varia VX, you perform the tool change faster than your competitors. In addition, your driven tool adapts to your requirements in the future. Due to the modular interface, for each machining process, the ideal tool clamping can be selected.

• Tool change in less than 20 seconds

• One-hand operation

• Mechanically loaded tool ejection

• Transverse force-free clamping of inserts

• Safe torque transmission

• Large selection of adapters (collet, Weldon, milling arbor, hydraulic expansion, shrinking)

• Tightening torque of 6 Nm must be observed!

Tapered roller bearings (KR) - extraordinarily loadable.

• Recommended for machining operations with high torques (e.g.: milling operations with large diameters, threading operations, interrupted cut machining)

• Increase of tool life

• Reduction of service intervals

• Simultaneous radial and axial loads can be easily absorbed

Double toothing (Traub license)

• VDI shank double toothed.

• Tool holder can be rotated 180°.

• Note: Rotatability may be restricted by alignment systems (e.g. Trifix).

• Ceramic based sealing elements

• 0 - 70 bar coolant pressure

• Dry running capability without restrictions

• Speeds up to 12,000/min

• Up to 60% reduced heat generation

• Long service life - low maintenance costs

• Seal kit for the latest generation of internal coolant supply systems

Catalogs

No catalogs are available for this product.

See all of EWS Weigele GmbH & Co. KG‘s catalogsOther EWS Weigele GmbH & Co. KG products

VDI Tool Holders [DIN69880 / ISO10889]

Related Searches

- Chuck

- Milling chuck

- Machining tool holder

- Collet chuck

- Drilling chuck

- DIN chuck

- Collet tool holder

- Milling tool holder

- Drilling tool holder

- DIN tool holder

- Taper shank chuck

- ER collet chuck

- Taper shank tool holder

- Modular chuck

- Tool holder for turning applications

- Cutting tool holder

- Quick-change chuck

- Milling collet chuck

- Quick-change tool holder

- Weldon chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.