- Industrial machines and equipment

- Surface Treatment Equipment

- Vacuum chamber

- EXACT DISPENSING SYSTEMS

Vacuum chamber

Add to favorites

Compare this product

Description

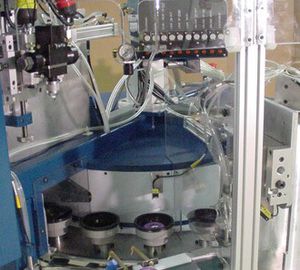

Exact Dispensing Systems offers a line of vacuum chambers and dispensing systems for customers involved in vacuum potting or vacuum encapsulation applications. These systems provide a proven solution for maintaining a dispensing environment which is free from air. Applications include potting or encapsulating of connectors, coils and other electronic components. The vacuum process provides improved impregnation in difficult to reach areas (i.e. connection pins, under circuit boards) and ensures void free encapsulation. With the advent of quick setting resins a user can, in some cases, perform vacuum potting of components and ship them the same day.

A typical configuration will consist of a single component dispense unit or a two component meter, mix and dispense system, a 24″ x 24″ x 24″ vacuum chamber with a clear acrylic door and a 22″ diameter platen, plus a high quality rotary vane vacuum pump. Smaller chambers are available, based on specific customer needs.

Controls can run anywhere from a completely manual system with hand crank linkage on the platen, to a system that features fully automatic positioning of both the platen and dispense head. The latter provides a complete auto-cycle for multiple parts production, and can include soak and dwell parameters. The system is designed to accommodate typical vacuum encapsulation process parameters (200 to 2 Torr), and pulldown times from 30 seconds to 2½ minutes. Higher Torr ratings and faster pull down times are available with optional vacuum pumps.

The vacuum chamber and dispensing systems may be purchased as stand alone products for applications other than vacuum encapsulation or vacuum potting.

Catalogs

No catalogs are available for this product.

See all of EXACT DISPENSING SYSTEMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.