- Machine-tools

- Machine Tool Accessory

- Motor-driven rotary table

- EXPERT-TÜNKERS GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

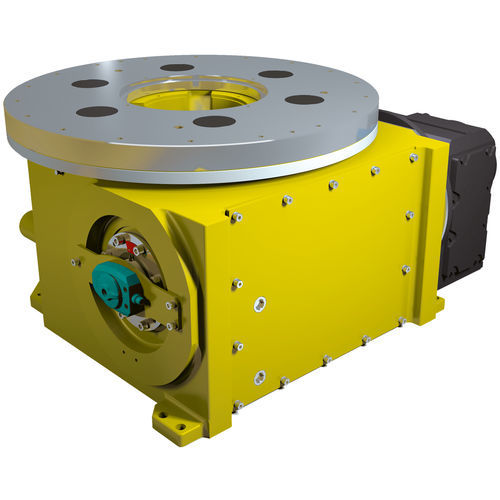

Motor-driven rotary table EDX serieshorizontalfor welding

Add to favorites

Compare this product

Characteristics

- Operation

- motor-driven

- Configuration

- horizontal

- Applications

- for welding

- Diameter

Min.: 360 mm

(14 in)Max.: 1,350 mm

(53 in)

Description

The rotary tables and trunnion drives of the EXPERT-TÜNKERS EDX series are precision indexer with fixed pitch and maximum torque. They are used for dynamic cycles of loads up to 20 tons. The drive takes place via an energy-efficient geared three-phase motor. A characteristic of EDX Series rotary tables is the fact that the dial plate is continuously driven by two cam followers. In addition, this double meshing of the roller pins ensures virtually zero-backlash locking of the turntable plate in the operating position. Alternatively, this can be achieved by widening the zero position. The indexing positions of the rotary table are defined in the motion profile specified in the indexing cam. Most common, partitions are 2-stop = 180°, 3-stop = 120° and 4-stop = 90°. Individual solutions are available on request.

Typical applications for EXPERT-TÜNKERS turntables are, for example, the change of work pieces in body shop welding systems, the insertion and removal of work piece carriers, or as a turntable for clocked work sequences in series production. The EDX Series of rotary tables are not only suitable for conventional use as rotary tables but also as trunnion drive units with a horizontal axis of rotation. These trunnion systems can provide several tooling’s for flexible production lines. The EDX Series of rotary tables are not only suitable for conventional use as rotary tables but also as trunnion drive units with a horizontal axis of rotation. These trunnion systems can provide several toolings for flexible production lines.

Catalogs

Rotating

34 Pages

Positioning Indexing Rotating

31 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.