- Production Machines

- Plastics Processing

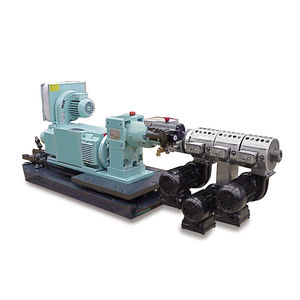

- Single-screw extruder

- Extrudex Kunststoffmaschinen GmbH

Single-screw extruder EN seriesgrooved feed

Add to favorites

Compare this product

Characteristics

- Number of screws

- single-screw

- Other characteristics

- grooved feed

- Screw diameter

Min.: 20 mm

(0.8 in)Max.: 150 mm

(5.9 in)

Description

EXTRUDEX extruders with grooved intake zones provide significant benefits including:

High pressure build-up and high pressure stability

High specific throughput rates

High intake and output consistency

These benefits are realized with all thermoplastic resins which are suited for solid-phase transport within grooves, i.e. which exhibit low "outer friction". Process-relevant components such as the screw and the grooved barrel are designed and/or optimized in accordance with the intended application at hand.

EXTRUDEX Grooved-Barrel Extruders

Standard Designs

EXTRUDEX grooved-barrel extruders are available in standard versions with screw diameters from 20 to 150 mm and screw lengths of 25 L/D and 30 L/D.

All EXTRUDEX extruders carry CE marking certifying full compliance with corresponding EU standards.

Catalogs

No catalogs are available for this product.

See all of Extrudex Kunststoffmaschinen GmbH‘s catalogsOther Extrudex Kunststoffmaschinen GmbH products

Extruders

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Pipe extrusion line

- Multilayer extrusion line

- PVC extrusion line

- Polypropylen extrusion line

- Single-screw screw extruder

- Polyethylene extrusion line

- Twin-screw extrusion line

- PVC screw extruder

- Laboratory screw extruder

- Single layer extrusion line

- PC extruder

- Underwater pelletizer

- Water pipeline extrusion line

- 3-layers extrusion line

- Calibration tank

- Extrusion line for medical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.