- Power Transmission - Mechanical components

- Bearing and Linear Guide

- Roller guidance system

- Exxellin Linear GmbH & Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

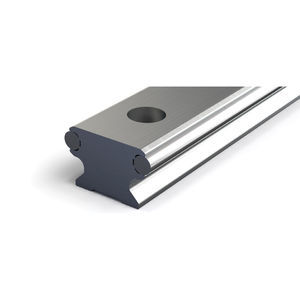

Roller guidance system ELFS seriesprecisionhigh-precisionsteel

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Other characteristics

- track, precision, steel, high-precision

- Rail length

3,000 mm, 6,000 mm

(118.11 in, 236.22 in)- Rail width

12.2 mm, 15 mm, 20 mm, 34 mm

(0.48 in, 0.59 in, 0.79 in, 1.34 in)

Description

ELFS support rails are composite construction:

▪ An high-precision aluminum base element accommodates hardened and polished precision steel shafts that are used as tracks for track rollers.

▪ The special rolling-in process ensures the extremely robust bond of the steel shafts to the aluminum base element.

Accuracy of ELFS support rails

The parallelity values specified are determined using differential measurement. The straightness values of the finely aligned support rails are better than DIN EN 12020.

Installation

▪ Lightly tighten screws

▪ Align support rails

▪ Tighten screws with tightening torque

For high loads, use washers that meet DIN 433 requirements. If installed with no side stop, comply with permissible side loads.

Lubrication

The track of the guide should be lubricated to avoid damage by tribocorrosion. The required intervals between lubrication depends on the type of application and environmental conditions. Reddish discoloration on the track or on the outer ring of the rollers is a sign of tribocorrosion and a lack of

lubrication.

Special conditions for use

Under certain conditions of use, such as vibrations, alternating loads under high acceleration in combination with too soft connection structures, or incompletely supported support rails, the rolled-in steel shafts may drift by several millimeters in the aluminum base element. Where necessary, a positive self-locking axial support is recommended.

Catalogs

ELF

6 Pages

Other Exxellin Linear GmbH & Co. KG products

Track roller guidance system

Related Searches

- Linear bearing

- Linear ball bearing

- Metal shaft

- Block-bearing

- Axis cam follower

- Metal bearing housing

- Steel linear bearing

- Precision shaft

- Closed linear bearing

- Steel shaft

- Stainless shaft

- Smooth linear bearing

- Metal cam follower

- Guidance system

- Open linear bearing

- Single shaft

- Linear shaft

- Roller guidance system

- Compact linear bearing

- Track guidance system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.