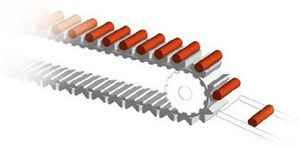

Slotted belt plastic

Add to favorites

Compare this product

Characteristics

- Type

- slotted

- Material

- plastic

Description

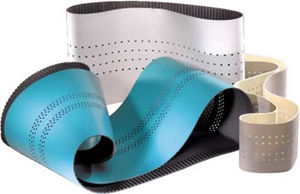

Hole Patterns & Shapes

Vacuum Belts provide positive holding power for very light weight products, such as paper, plastic film and fabrics. Hole size and pattern (percentage of open air) can be modified to meet the applications need. There are endless possibilities. There are some standard patterns available, but usually each unique application requires its unique hole pattern. A simple drawing with dimensioning is all that is required to have a die made for perforating. Please contact our Technical Department.

Note: For vacuum applications, it is possible under certain circumstances, to extrude urethane timing belts with cord spacing that allows for placing the holes between cords so that the cords are not cut during perforation.

Catalogs

No catalogs are available for this product.

See all of F.N. Sheppard‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.