- Products

- Catalogs

- News & Trends

- Exhibitions

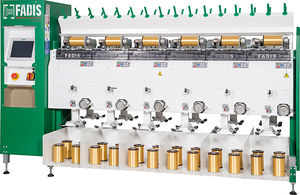

Yarn winding machine SINCRO M /RFM /FFM- PREMIUMpackageprocessprecision

Add to favorites

Compare this product

Characteristics

- Product application

- yarn

- Other characteristics

- precision, package, process, hank to cone

Description

Fadis is the only company in the world able to offer the most appropriate machine range to process elastic yarns, in the form of Packages, Fapp™, Muff and Hanks. In 2003 Fadis presented an important technological innovation, the Fapp™ (FAdis Precision Package), a low density package that is a perfect preparatory solution to then dye elastic yarns. The Fapp™ allows for wide retraction margins of the yarn during the dyeing phase, thus keeping a high residual elasticity percentage of the elasticized yarn. The starting point has been the introduction of SINCRO FFM, followed in 2007 by an even more innovative concept, the SINCRO M.

Therefore, with this now widely tested preparatory system, and the possibility of unwinding the FAPP™ with the SINCRO RFM SW rewinding machine with its “on-line” tension control, it is possible to obtain qualitative results quite similar to hank dyeing but with the same simplicity and economy typical of yarn package dyeing.

With the SINCRO FFM - PREMIUM and SINCRO T FFM - PREMIUM machines, it is possible to produce FAPP™ packages (FAdis Precision Package) with a low density, which allow retraction margins of the yarn during the dyeing phase, thus keeping a good residual elasticity percentage of the elasticized yarn.

Thanks to this more and more evolved technology, it is possible to process not only stretch polyamide yarns, but also all those elasticized yarns whose main prerogative is to maintain a high degree of residual elasticity after dyeing, such as for example, elasticized viscose, nylon PBT, polyester T400 and other similar yarns.

Related Searches

- Fadis winding machine

- Rewinder-winder

- Automatic winding machine

- Fadis yarn winding machine

- Automatic rewinder-winder

- Fadis precision winding machine

- Fadis package winding machine

- Fadis process winding machine

- Cone to cone winding machine

- Hank to cone winding machine

- Yarn rewinder-winder

- Heavy-duty winding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.