- Production Machines

- Forming Machine

- Mechanical press

- Fagor Arrasate S.Coop.

- Products

- Catalogs

- News & Trends

- Exhibitions

Hydraulic press 7SmechanicalformingCNC

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, mechanical

- Function

- forming

- Control

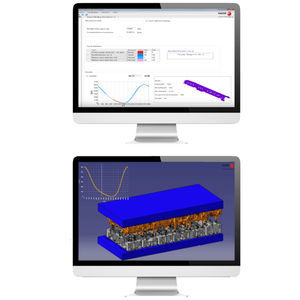

- CNC

- Other characteristics

- electronic, transfer

- Applications

- process

- Weight

400 kg

(882 lb)

Description

With more than 200 references in transfer presses, Fagor Arrasate has been supplying transfer presses for over 30 years, more than 20 of which have been spent manufacturing large transfer presses of over 3,500 tons. Our presses are fully automated upon delivery. We have our own automations that we have been developing for more than 20 years, such as transfer systems or pick-up destackers. In this way, at Fagor Arrasate we can offer our customers a 100% proprietary solution that guarantees optimal synchronization.

AUTOMATION EXPERTS

The automation process involves, in addition to the mechanical press itself and the electronic transfer, other electronic and mechanical components and accessories, such as loaders, clamps, software, as well as the dies and the auxiliary bar with the gripper and safety elements.

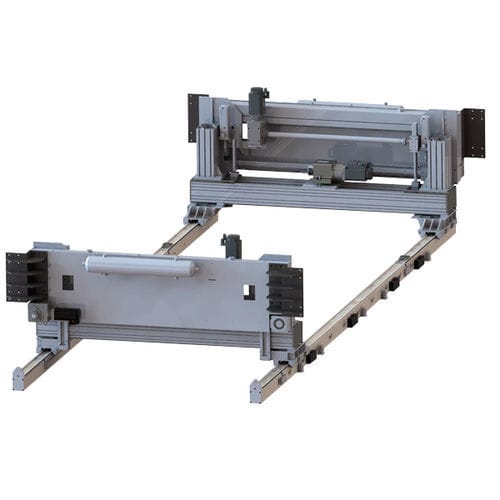

CL LONGITUDINAL DESTACKER

The optimal solution for production rates of up to 28 spm and blanks of up to 60 kg. As we can see, the structure consists of a single feeder and two loading carts so that the feeder can switch from one to the other, avoiding wasting time. This Destacker is used in some installations with feeding lines. At the end of the line there is a shear where the coil is cut and the loader collects the blank so as to feed the press.

CT TRANSVERSAL DESTACKER

Typically, the bottleneck of a transfer facility took place in the die and press, but it was rarely in automation. With the development of servo technology, the bottleneck may be in automation. Our CT Transversal destacker has been upgraded to run at up 40 spm with blanks of up to 80 kg.

Catalogs

No catalogs are available for this product.

See all of Fagor Arrasate S.Coop.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.