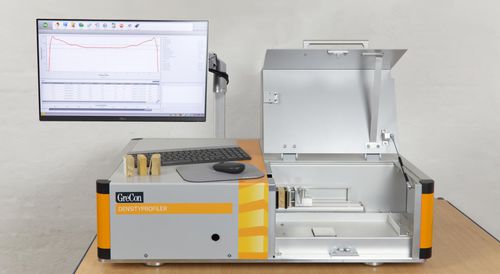

The Laboratory Measuring System DENSITYPROFILER conveniently measures the raw density profiles of wood based panels within seconds. The density profiles as well as the measured values are represented on a monitor and stored individually for each panel sample.

The high-precision measuring results are used to adapt the production process quickly.

Benefits at a glance

Density profile available within a few seconds

Several profiles superimposed in one graphic = production control

Clear display of the effects of changes in the production

Easy data export in common data formats

Can be combined with other laboratory measuring devices

Preparation of samples during an ongoing measuring process

Measuring method

The sample support with the samples is led through the measuring system via a linear slide to determine the density distribution over the cross-section of the sample thickness. It is possible to record very precisely measurements with a speed of 0.01 mm to 4 mm per second thanks to the measurement transducer consisting of an X-ray combination.

All recorded measured data are analysed and displayed in the visualisation of the DENSITYPROFILER and can be exported, if requested. Measurement is carried out in some few and easy steps.

The first step is the entry of the sample parameters into the visualisation software. The sample parameters can be directly transferred to the software via the slide gauge and the balance, both connected to the DENSITYPROFILER. Optionally, it is possible to equip the DENSITYPROFILER with internal sensors for a fully automatic measurement of the sample geometry and the weight.