- Production Machines

- Machine for the electronics industry

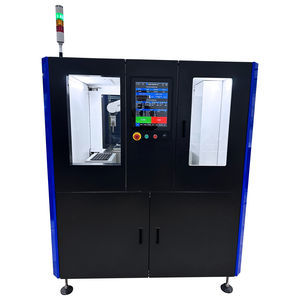

- Lead former

- Fancort Industries, inc.

Lead former

Add to favorites

Compare this product

Description

Fancort Pneumatic Presses: 1 to 5 tons. American Built & Easily Customizable. Low Volume/Lowest Cost.

Press-Fit machinery

Fancort designs and builds fixtures and bench-top pneumatic presses for pressing compliant pin connectors into circuit boards. Fancort's pneumatic air presses are quiet, heavy-duty, and deliver smooth operation. Designed for applications requiring 1 ton or more, these very sturdy pneumatic air presses come in several models of different force ranges

Press-Fit technology

Is the insertion of flexible or rigid connector pins into plated through holes (PTHs) of printed circuit boards without soldering. Fancort offers a complete range of machines and tooling for low to automated high volume machines. Our equipment has been used by the world’s largest electronics manufacturers.

Advantages of press-fit technology VS soldering

• Prevention of thermal stress on the PCB and no soldering

• Eliminating pins damage or breakage, solder bump or flux residue, etc.

• Avoidance of short, cold solder connection, corrosion, etc.

• Enable Plugins to connect with plugs directly, and no need for screws

• Connectors with long pins can be connected from the backside of the PCB, for no soldering

• Reparability that the connector or a single pin can be replaced easily

• Stable and low contact resistance, good high frequency characteristics

• No need to wash PCBs and prevention of polluted substances like fluxes for no soldering

• High efficiency and low cost

• Green technology , no solder or flus to store or recycle

Catalogs

No catalogs are available for this product.

See all of Fancort Industries, inc.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.