- Metrology - Laboratory

- Inspection and Monitoring

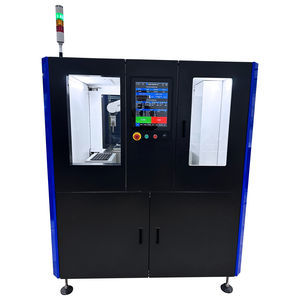

- Laser inspection system

- Fancort Industries, inc.

3D inspection system Veri-Spec 3Dlaservideo visionrobotic

Add to favorites

Compare this product

Characteristics

- Technology

- 3D, laser, video vision

- Operational mode

- robotic

- Type

- measurement

- Configuration

- custom

- Other characteristics

- high-resolution

Description

Introducing Fancort's Veri-Spec 3D, a high-resolution/precision 3D vision inspection system for SMT gullwing lead-forming. The Veri-Spec 3D uses a fully featured HMI where new parts can be introduced in seconds. Options include data logging to internal and/or external databases and seamless integration into the robotic Fancort Tinning Cell and SmartFlex.

The SMT Vision inspection station will be able to take Flat Packs or Quad Flat Packs and automatically inspect the leads based on a set of user-entered parameters. This means entirely new packages can be introduced to the inspection system and be ready to inspect within seconds.

The 3D vision inspection system can inspect parts based on user-defined tolerances. Recipes can save package dimensions and tolerance settings, allowing part changes to be one click away.

User Interface

User interface can display simplified “GO/NO-GO” indications or be set to display advanced measurement viewing and visualizations.

Data Logging

All process data can be logged locally and/or remotely to a SQL server. Logging options can be chosen to include only the data relevant to the customer.

- MEASUREMENT VALUES

- PROCESS SETTINGS AND VALUES

- 3D POINT CLOUD DATA

- PART NUMBERS AND CUSTOM DATA

Process Control

Viewable control charts for tracking process stability under the influence of a range of factors.

High-Precision Line Scanner / Laser Scanner

The scanner has a minimum resolution of 4 μm and a repeatability of 0.4 μm (height) / 0.5 μm (width).

Lead Processing Inspection Systems

Each lead is individually processed to reduce noise issues on highly reflective surfaces. Noise is eliminated without compromising scan data.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Fancort Industries, inc.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.