- Production Machines

- Cutting Machine

- Laser cutting machine

- Farley Laserlab

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

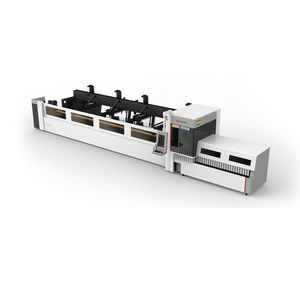

Laser cutting machine TP 1212Ffor stainless steelfor carbon steelfor metal pipes

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for stainless steel, for carbon steel

- Product handled

- for metal pipes

- Control type

- CNC

- Applications

- for construction machinery, for shipbuilding

- Workpiece loading

- automated loading/unloading

- Phase

- three-phase

- Configuration

- large-format, 3-axis

- Other characteristics

- automatic, semi-automatic, precision, high-efficiency, economical, modular

- X travel

Max.: 12,500 mm

(492.13 in)Min.: 0 mm

(0 in)- Y travel

Max.: 300 mm

(11.81 in)Min.: 0 mm

(0 in)- Z travel

Max.: 180 mm

(7 in)Min.: 0 mm

(0 in)- Tube diameter

Max.: 380 mm

(15 in)Min.: 20 mm

(1 in)- Operating pressure

Max.: 0.8 MPa

Min.: 0.5 MPa

- Overall length

2,500 cm

(984 in)- Overall width

650 cm

(256 in)- Height

280 cm

(110 in)

Description

Fully automatic production [precision cutting of super long and overweight coffins] Brand support [economical and reliable service] Application fields: electrical tower, infrastructure, ship bridge, prefabricated building, intelligent logistics and other industries

Fully Automatic Servo Control Loading And Unloading System

It can realize the smooth loading and unloading of heavy pipes with different lengths, sizes and shapes, reduce the scraping between work pieces, seamlessly connect with the equipment, and achieve semi-automatic or fully automatic production with the machine host, so as to shorten the working time and improve the working efficiency.

Modular Bed Design

Disruptive innovation can quickly respond to the needs of customers in multiple scenarios. It can realize the free combination of loading, unloading and cutting beds of 6 meters to 15 meters in the way of building blocks according to the customer's plant area and actual production needs.

Integrated High Rigidity And High Precision Cast Iron Pneumatic Chuck

With higher cutting accuracy, stability and shock absorption of the machine tool, it can suppress the huge vibration generated by the cutting process of super long and overweight steel pipes and avoid laser cutting defects; The machining accuracy of small holes reaches 0.1mm, which completely solves the problem of non-circular cutting of small holes in heavy pipes.

Catalogs

No catalogs are available for this product.

See all of Farley Laserlab‘s catalogsRelated Searches

- HG Farley LaserLab Co cutting machine

- HG Farley LaserLab Co metal cutting machine

- HG Farley LaserLab Co CNC cutting machine

- HG Farley LaserLab Co laser cutting machine

- HG Farley LaserLab Co cutting machine for industrial applications

- HG Farley LaserLab Co automatic cutting machine

- Knife cutting system

- HG Farley LaserLab Co high-precision cutting machine

- HG Farley LaserLab Co sheet metal cutting machine

- HG Farley LaserLab Co high-speed cutting machine

- HG Farley LaserLab Co fiber laser cutting machine

- HG Farley LaserLab Co tube cutting machine

- HG Farley LaserLab Co precision cutting machine

- HG Farley LaserLab Co aluminum cutting machine

- HG Farley LaserLab Co stainless steel cutting machine

- HG Farley LaserLab Co sheet cutting machine

- HG Farley LaserLab Co metal fabrication cutting machine

- HG Farley LaserLab Co cutting machine for the automotive industry

- HG Farley LaserLab Co CE cutting machine

- HG Farley LaserLab Co high-performance cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.