- Production Machines

- Cutting Machine

- Laser cutting machine

- Farley Laserlab

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

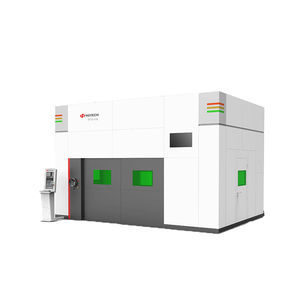

Laser cutting machine SF6020for metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Associated function

- trimming, for welding

- Applications

- for industrial applications, for the automotive industry

- Phase

- three-phase

- Configuration

- compact, 5-axis

- Other characteristics

- automatic, high-precision, high-speed, CE, high-performance, high-efficiency, economical, 3D

- X travel

6,000 mm

(236.22 in)- Y travel

2,000 mm

(78.74 in)- Z travel

680 mm, 800 mm, 1,000 mm, 1,200 mm, 1,500 mm

(27 in, 31 in, 39 in, 47 in, 59 in)- Cutting speed

Min.: 50 m/min

Max.: 100 m/min

- Laser power

Min.: 2,000 W

Max.: 6,000 W

- Repeatability

0.02 mm

(0.0008 in)

Description

The SF series of 3D five-axis laser cutting machines are designed for customers in the automotive, mould, home appliance, engineering machinery, hardware, medical equipment, fitness equipment and other fields. They are characterised by high precision, high speed, low cost of ownership, simple operation and maintenance, and can meet the needs of different production schedules.

The 3D 5-Axis laser machine series is characterized by high precision, high speed, high efficiency, high stability, leading technology in the world, compact structure, simple operation and easy maintenance. The products are widely used in automotive, mould, household appliances, engineering machinery, ships, hardware, medical equipment, fitness equipment and other fields to meet the requirements of various metal workpiece surface cutting and trimming.

• Compared with robot 3d cutting, it has fast speed and high precision;

• Compared with the traditional CARBON dioxide laser cutting machine, the use cost is low, the operation is simple, the maintenance is convenient.

Technical Advantages

• Extensibility

In addition to 3D cutting of workpieces, the machine can also be used for flat cutting and can be equipped with welding modules for welding functions to meet different customer needs.

• Stability

The double-drive gantry structure provides high stability and guarantees long-term high-speed, high-precision and stable cutting。

• Safety

The machine is equipped with a fully sealed laser protection room, with a light curtain to ensure the safety of personnel in the working table area, and the overall safety protection of the machine complies with CE international safety standards.

Catalogs

No catalogs are available for this product.

See all of Farley Laserlab‘s catalogsRelated Searches

- HG Farley LaserLab Co cutting machine

- HG Farley LaserLab Co metal cutting machine

- HG Farley LaserLab Co CNC cutting machine

- HG Farley LaserLab Co laser cutting machine

- HG Farley LaserLab Co cutting machine for industrial applications

- HG Farley LaserLab Co automatic cutting machine

- Knife cutting system

- HG Farley LaserLab Co high-precision cutting machine

- HG Farley LaserLab Co sheet metal cutting machine

- HG Farley LaserLab Co high-speed cutting machine

- HG Farley LaserLab Co fiber laser cutting machine

- HG Farley LaserLab Co tube cutting machine

- HG Farley LaserLab Co precision cutting machine

- HG Farley LaserLab Co aluminum cutting machine

- HG Farley LaserLab Co stainless steel cutting machine

- HG Farley LaserLab Co sheet cutting machine

- HG Farley LaserLab Co metal fabrication cutting machine

- HG Farley LaserLab Co cutting machine for the automotive industry

- HG Farley LaserLab Co CE cutting machine

- HG Farley LaserLab Co high-performance cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.