- Production Machines

- Cutting Machine

- Laser cutting machine

- Farley Laserlab

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

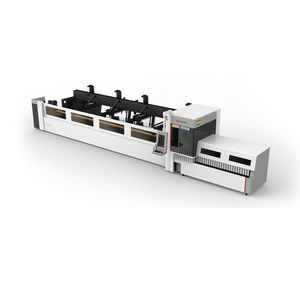

Laser cutting machine TP12036Mfor stainless steelfor carbon steeltube

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for stainless steel, for carbon steel

- Product handled

- tube

- Control type

- CNC

- Applications

- for construction machinery

- Configuration

- 3-axis

- Other characteristics

- automatic, high-precision, high-speed, high-efficiency, heavy-duty, economical, modular

- X travel

Max.: 800 mm

(31.5 in)Min.: 0 mm

(0 in)- Y travel

Max.: 12,200 mm

(480.31 in)Min.: 0 mm

(0 in)- Z travel

Max.: 350 mm

(14 in)Min.: 0 mm

(0 in)- Tube diameter

Max.: 360 mm

(14 in)Min.: 20 mm

(1 in)- Laser power

3,000 W, 4,000 W, 6,000 W

- Repeatability

0.05 mm

(0.002 in)- Operating pressure

Max.: 0.8 MPa

Min.: 0.5 MPa

- Overall length

1,930 cm

(760 in)- Overall width

650 cm

(256 in)- Height

280 cm

(110 in)- Weight

23 t

(25.35 us ton)

Description

TP10036M<10036M 3 chucks (side-hung) heavy-load laser tube cutting machine integrates CNC technology, laser cutting, precision machinery and automatic control. It has high speed, high precision, high efficiency and high economic benefits, and can meet the cutting requirements of ultra-long and ultra-heavy tubes in industries such as bridges and ships, engineering machinery, electric power tower, assembly building, tunnel traffic, etc. It has outstanding advantages for processing of ultra-long and ultra-heavy metal tubes and sectional materials. It has high precision, high speed, good equipment stability, and is convenient to operate, and can realize volume production.

TP10036M<10036M 3 chucks (side-hung) heavy-load laser tube cutting machine integrates CNC technology, laser cutting, precision machinery and automatic control. It has high speed, high precision, high efficiency and high economic benefits, and can meet the cutting requirements of ultra-long and ultra-heavy tubes in industries such as bridges and ships, engineering machinery, electric power tower, assembly building, tunnel traffic, etc.

It has outstanding advantages for processing of ultra-long and ultra-heavy metal tubes and sectional materials. It has high precision, high speed, good equipment stability, and is convenient to operate, and can realize volume production.

• Adaptability:Can achieve max. 1T heavy tube processing, the processing diameter is up to 360mm (Φ360mm, □250*250mm).

• Economy:3-chucks zero-tailing cutting, which can realize the cutting processing of loading of 12-meters all in one piece material, unloading of 6-meters all in one piece material and zero-tailing processing.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Farley Laserlab‘s catalogsRelated Searches

- HG Farley LaserLab Co cutting machine

- HG Farley LaserLab Co metal cutting machine

- HG Farley LaserLab Co CNC cutting machine

- HG Farley LaserLab Co laser cutting machine

- HG Farley LaserLab Co cutting machine for industrial applications

- HG Farley LaserLab Co automatic cutting machine

- Knife cutting system

- HG Farley LaserLab Co high-precision cutting machine

- HG Farley LaserLab Co sheet metal cutting machine

- HG Farley LaserLab Co high-speed cutting machine

- HG Farley LaserLab Co fiber laser cutting machine

- HG Farley LaserLab Co tube cutting machine

- HG Farley LaserLab Co precision cutting machine

- HG Farley LaserLab Co aluminum cutting machine

- HG Farley LaserLab Co stainless steel cutting machine

- HG Farley LaserLab Co sheet cutting machine

- HG Farley LaserLab Co metal fabrication cutting machine

- HG Farley LaserLab Co cutting machine for the automotive industry

- HG Farley LaserLab Co CE cutting machine

- HG Farley LaserLab Co high-performance cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.