- Production Machines

- Cutting Machine

- Laser cutting machine

- Farley Laserlab

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

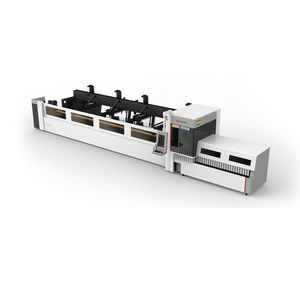

Laser cutting machine LT10032Wfor aluminumfor stainless steelfor carbon steel

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for aluminum, for stainless steel, for carbon steel

- Product handled

- tube

- Control type

- CNC

- Applications

- for industrial applications, for processing industry, for construction machinery, for agricultural vehicles

- Phase

- three-phase

- Configuration

- 3-axis

- Other characteristics

- automatic, high-precision, high-speed, high-efficiency, modular, horizontal

- X travel

Max.: 300 mm

(11.81 in)Min.: 0 mm

(0 in)- Y travel

Max.: 11,000 mm

(433.07 in)Min.: 0 mm

(0 in)- Z travel

Max.: 180 mm

(7 in)Min.: 0 mm

(0 in)- Tube diameter

Max.: 320 mm

(13 in)Min.: 20 mm

(1 in)- Laser power

3,000 W, 4,000 W, 6,000 W

- Repeatability

0.05 mm

(0.002 in)- Operating pressure

Max.: 0.8 MPa

Min.: 0.5 MPa

- Overall length

1,730 cm

(681 in)- Overall width

650 cm

(256 in)- Height

280 cm

(110 in)

Description

TP10032W<10032W 3 chucks (horizontal) laser tube cutting machine integrates CNC technology, laser cutting, and precision machinery into one, with good adaptability. It has great advantages for medium and heavy tube processing. It is mainly used for cutting of carbon steel tube, stainless steel tube, aluminum alloy tube (square tube, round tube, OB tube, sectional materials) and other tubes. It is the first choice for noncontact metal tube processing industry because of its professionalism, efficiency, high cost performance. It is widely used in petroleum tubeline, bus manufacturing, construction machinery, shelves and container, agricultural and forestry machinery, ladder and guardrail, laser processing services and other machine manufacturing or tube processing industry.

• Extensibility:Super large HMI interactive interface , with multi functions such as process database, gra phic display, automatic fixture control, program quick editing and modification etc.

• Precision:3-chucks linkage cutting, large cutting load, high precision, can achieve zero tailing cutting

• Efficiency:Equipped with a fully automatic bundling and loading system, with high automatic production efficiency.

• Safety:The machine tool is equipped with fully enclosed machine tool cover, the overall safety protection of the machine tool meets the highest international standards.

• Flexibility:Modular design, can be customized according to customer requirements.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Farley Laserlab‘s catalogsRelated Searches

- HG Farley LaserLab Co cutting machine

- HG Farley LaserLab Co metal cutting machine

- HG Farley LaserLab Co CNC cutting machine

- HG Farley LaserLab Co laser cutting machine

- HG Farley LaserLab Co cutting machine for industrial applications

- HG Farley LaserLab Co automatic cutting machine

- Knife cutting system

- HG Farley LaserLab Co high-precision cutting machine

- HG Farley LaserLab Co sheet metal cutting machine

- HG Farley LaserLab Co high-speed cutting machine

- HG Farley LaserLab Co fiber laser cutting machine

- HG Farley LaserLab Co tube cutting machine

- HG Farley LaserLab Co precision cutting machine

- HG Farley LaserLab Co aluminum cutting machine

- HG Farley LaserLab Co stainless steel cutting machine

- HG Farley LaserLab Co sheet cutting machine

- HG Farley LaserLab Co metal fabrication cutting machine

- HG Farley LaserLab Co cutting machine for the automotive industry

- HG Farley LaserLab Co CE cutting machine

- HG Farley LaserLab Co high-performance cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.