- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

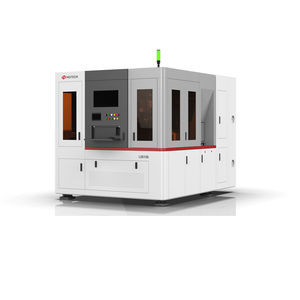

Laser PCB depaneling machine SMT compact

Add to favorites

Compare this product

Characteristics

- Type

- laser

- Other characteristics

- compact

Description

It is suitable for PCBA production line. Offline/online design can be selected according to needs. Fully automatic laser cutting is carried out through the equipment high-precision control system and industrial vision system to realize the high-precision cutting requirements of PCBA enterprises without dust and deformation.

It is suitable for PCBA production line. Offline/online design can be selected according to needs. Fully automatic laser cutting is carried out through the equipment high-precision control system and industrial vision system to realize the high-precision cutting requirements of PCBA enterprises without dust and deformation.

Equipment characteristics

• Selecting world-class lasers, with good beam quality and high cutting quality, can complete fine processing with a minimum line width of 10um ( depending on the material )

• The equipment has a compact structure,small size, and easy to be embedded in various SMT production lines

• Professional cutting vision control system,compatible with the difference of incoming materials from different board factories, and realize batch quality control

• High cutting accuracy, overall cutting accuracy of 25um, high equipment stability

• Both the light path system and the working platform are made of marble, with goodprocessing flatness and stable precision

• Can be connected to MES system to achieve data interoperability

VIDEO

Catalogs

SMT PCB Laser Solution

10 Pages

PCB LASER MARKING MACHINE

3 Pages

Other Farley Laserlab products

Specialized Products for PCB Microelectronic

Related Searches

- HG Farley LaserLab Co cutting machine

- HG Farley LaserLab Co metal cutting machine

- HG Farley LaserLab Co CNC cutting machine

- HG Farley LaserLab Co laser cutting machine

- HG Farley LaserLab Co automatic cutting machine

- HG Farley LaserLab Co high-precision cutting machine

- HG Farley LaserLab Co marking machine

- HG Farley LaserLab Co high-speed cutting machine

- HG Farley LaserLab Co laser marking machine

- HG Farley LaserLab Co metal marking machine

- HG Farley LaserLab Co high-efficiency cutting machine

- HG Farley LaserLab Co plastic marking machine

- HG Farley LaserLab Co cutting machine with automated loading

- HG Farley LaserLab Co industrial marking machine

- HG Farley LaserLab Co automatic marking machine

- HG Farley LaserLab Co high-speed marking machine

- HG Farley LaserLab Co fiber laser marking machine

- Aluminum marking workstation

- HG Farley LaserLab Co processing industry cutting machine

- HG Farley LaserLab Co electronic component marking machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.