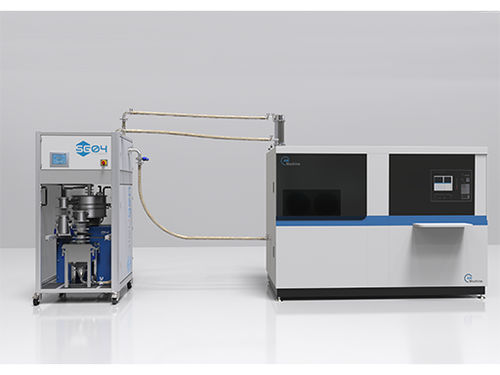

Sievgen 04-S (SG 04-S) is an environmentally sealed ultrasonic sieve that uses a touch screen interface to automate metal powder sieving directly from an Additive Manufacturing (AM) machine.

A highly automated, ultrasonic sieve for recycling and processing metal powders.

To meet the needs of our additive manufacturing customers, our powder processing system has been developed to reduce both downtime and operator involvement.

The unit opens up to reveal the sieve at the heart of the process, allowing unhindered cleaning access and minimising turnaround times between batches or material changes. Its straightforward interface enables automation of the process, releasing the operator from continual supervision of the recycling process, whilst still keeping them in control.

Controlled. Efficient. Safe.

Batch weight control – control of machine through weighing of processed powder.

Highly automated user interface – intuitive menu based system.

Quick clean – accessible system (on sliding drawer deck) for quick clean or part change.

A complete conveying and sieving solution – compact, all in one design, easy to manoeuvre.

High throughput ultrasonic sieving – aids throughput whilst maintaining high single pass efficiency.

Enhanced filtration – Option to include ULPA (Ultra Low Particulate Air) secondary filter, as well as first stage HEPA filter health monitoring.

Flexible Solution – optional layout to allow larger containers (30litres plus) to be wheeled up to the unit and option to add conveying unit to transfer powders directly from unit to AM machine.