- Hydraulics - Pneumatics

- Pump

- Rotary vane pump

- Fasttrack Engineering Propriety Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary vane pump for food productselectricfor the food industry

Add to favorites

Compare this product

Characteristics

- Technology

- rotary vane

- Fluid

- for food products

- Operation

- electric

- Domain

- for the food industry

Description

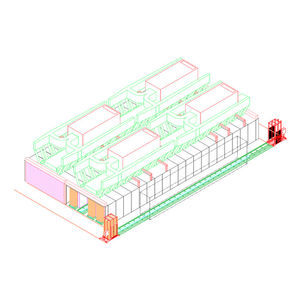

In recent years some of the leading mogul manufacturers made statements and implementations in regards to the universal pumping system,

(centre-in-shell) they are listed below.

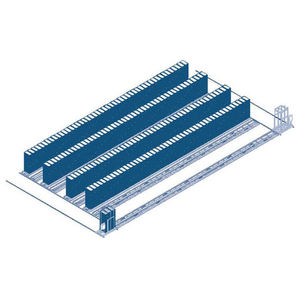

- You will require a full tray pump to make a centre filled article (centre-in-shell).

- You will require a stationary pump.

- You must lift the tray to achieve a proper suck back, during the depositing displacement.

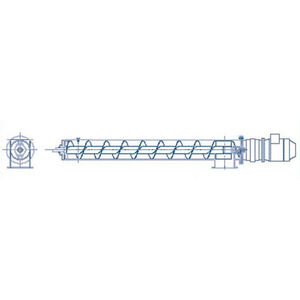

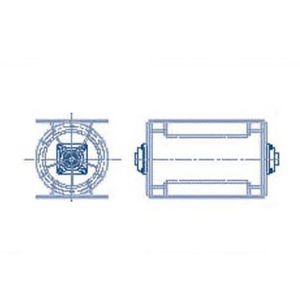

- You will require a rotary valve pumping system, otherwise you will not achieve a proper deposit, having the centre volume in the middle of the article.

All the above seem to have been adopted by the majority of candy producers, the first centre-in-shell depositing pump was invented for a mogul operation in the early 1970s and it has been reinvented over the years on several occasions.

Fast Track Engineering's founder was involved in the development of the universal pumping system during the early 1970s and subsequent redevelopment on each of the other occasions, he realised the shortcomings and benefits of this pumping system and was surprised when the above statements were made and therefore decided to set the record straight.

VIDEO

Other Fasttrack Engineering Propriety Limited products

Products and Services

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.