- Industrial machines and equipment

- Furnace and Heat Treatments

- Fluidized bed dryer

- Fasttrack Engineering Propriety Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

Cooler dryer fluidized bedbatchfor the food industry

Add to favorites

Compare this product

Characteristics

- Technology

- fluidized bed

- Batch/continuous

- batch

- Applications

- for the food industry

- Associated function

- cooler

- Other characteristics

- compact

Description

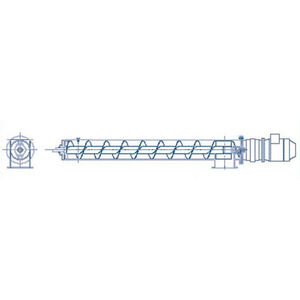

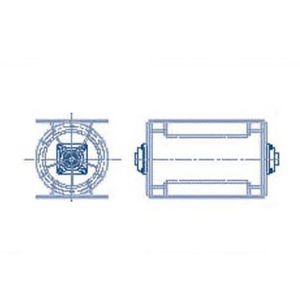

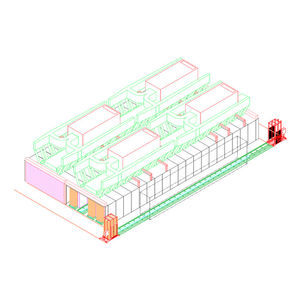

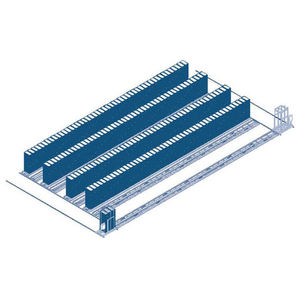

The FTE starch drying/cooling system is based on the fluidised bed principle, which is a reliable and efficient starch conditioning method. The system consists of the drying chamber with top mounted dust collector and is equipped with steam coils mounted on each side of the machine. The cooling chamber is of the identical design and is equipped with a number of cooling coils mounted on each side of the machine. The fans which are mounted in-front of the dust collector will create a negative air flow through the total system on each machine.

The starch on entry into the dryer or cooler will be entering into the air stream and will be subjected to hot and cold condition. In the heating cycle the moisture in the starch will be reduced, in the cooling cycle the starch will be cooled down to a temperature where the next produced product can be deposited into.

It is important that that the starch moulding equipment, (Mogul and starch conditioning) is working in harmony together to achieve a product which the customer appreciates, in regards to appearance, taste and texture and will purchase again, which all relates to the above moulding equipment, which can be purchased from Fast Track Engineering.

- Highly efficient in moisture removal.

- Aeration of starch during the drying and cooling process.

- Energy-saving.

- Compact in design.

- Provision of uniform texture and quality during moulding and curing process.

- System provides customer requirements from low throughput to machines with maximum throughput.

- Provision of customised engineering advice for individual client needs.

Other Fasttrack Engineering Propriety Limited products

Products and Services

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.