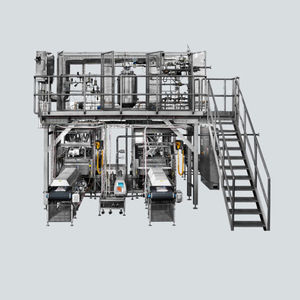

Process sterilizer for the food industry

Add to favorites

Compare this product

Characteristics

- Laboratory/process

- process

- Applications

- for the food industry

Description

The range of sterilizers manufactured by FBR ELPO before the aseptic filling also includes the scraped surface version.

These equipment can be used with excellent results in the processing of products for the food industry, for ketchup and sauces even with pieces, for dense, semi-dense, concentrated and pulpy products, as well as for fruit and tomato centrifuges.

In the confectionery sector, they are successfully used in the processing of cream, ice cream preparations and dairy products in general. FBR ELPO offers models of different diameter and length, depending on the production capacity to be satisfied.

Each module consists of:

– stainless steel external tube

– Internal roating shaft in AISI 316 stainless steel, with movable scrapers

– special mechanical seal with steam barriers

– electric motorization with speed variator or speed reducer and inverter

Applications with deaerator and homogenizer are available.

All scraped surface sterilizers can be coupled to all the aseptic fillers produced by FBR ELPO.

Catalogs

No catalogs are available for this product.

See all of FBR-ELPO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.