Automatic filler MONOBLOC containerfruit juicefor dairy products

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- container

- Product applications

- fruit juice, for dairy products

- Domain

- for the food industry

- Type

- aseptic

- Other characteristics

- compact

Description

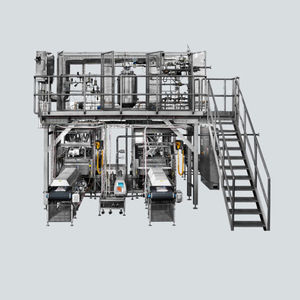

For customers having space problems, FBR ELPO manufactures the “MONOBLOCK” system, a version that includes both the sterilizer and the aseptic filler on a single frame, as well as the product buffer tank.

A solution that ensures enormous advantages, in terms of:

– compact overall dimensions;

– costs saving;

– greater functionality and reliability.

The “MONOBLOCK” model has been designed to treat different types of products, such as concentrates, diced tomatoes, fruit and tomato puree, concentrates of clear fruit juices and dairy products.

Depending on the product to be treated, FBR ELPO offers three different “MONOBLOCK” groups:

– Monoblock with scraped surface sterilizer, with operating capacity up to 5.000 kg/h

– Monoblock with tube in tube sterilizer, with operating capacity up to 5,000 kg/h

– Monoblock with plate sterilizer, with operating capacity up to 10,000 kg/h

Catalogs

No catalogs are available for this product.

See all of FBR-ELPO‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Multi-head filler

- Container filler

- Bag filler

- Compact filler

- Filler with conveyor

- Manual filler

- Sauce filler

- Drum filler

- Filler with 2 heads

- Fruit juice filler

- Aseptic filler

- Aseptic filling system

- Milk filler

- Water filling line

- Dairy product filler

- Wine filling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.