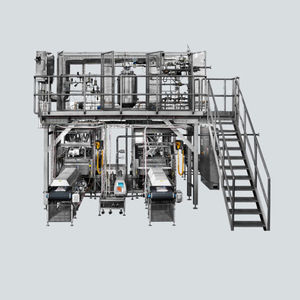

Aseptic filler MUSTANGautomaticbag-in-boxfor liquids

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bag-in-box

- Product applications

- for liquids, for ice cream production

- Number of heads

- with 2 heads

- Other characteristics

- aseptic

- Throughput

1,200 p/h

- Volume

Min.: 1.5 l

(0.4 gal)Max.: 20 l

(5.3 gal)- Machine length

3,800 mm

(150 in)- Machine height

2,765 mm

(109 in)

Description

Achieving extremely high working capacities to satisfy the BAG IN BOX market.

It is possible now, thanks to the new completely automatic MUSTANG aseptic filler, built in stainless steel with double filling head with production capacity up to 1.200 bags/h.

Designed for the filling of a wide range of products, liquid and with pieces, low and high acid, such as milk, cream, ice-cream basis, natural fruit juices and concentrates, tea, tomato etc. the new MUSTANG filler can handle pre-sterilized bags from 1,5 to 20L with continuous module.

Thanks to its significant flexibility, the MUSTANG filler can work with bags that use any type of spout available on the BAG IN BOX market including those with pre-mix or post-mix dispensing pipes.

Spouts can be “short neck” or “long neck type”, placed in the centre or in the corner of the bag. Another distinctive feature is the possibility to sterilize the cap either with chemical agents and/or by using steam.

New components for high performance

The standard version allows the reception of the product directly from a sterilizer without needing the interposition of an aseptic tank (usually indispensable for this kind of machines).

An outlet roller conveyor allows the bag unloading on a conveyor belt that permits the further bag insertion inside the box. The cutter, which can be continuously adjusted by means of a wheel, permits a fast regulation of the format change. The sliding doors guarantee less space and more functionality.

Catalogs

No catalogs are available for this product.

See all of FBR-ELPO‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Multi-head filler

- Container filler

- Bag filler

- Compact filler

- Filler with conveyor

- Sauce filler

- Manual filler

- Drum filler

- Filler with 2 heads

- Fruit juice filler

- Milk filler

- Aseptic filler

- Aseptic filling system

- Water filling line

- Dairy product filler

- Wine filling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.