- Power Transmission - Mechanical components

- Bearing and Linear Guide

- Cylindrical plain bearing

- Federal-Mogul Deva GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

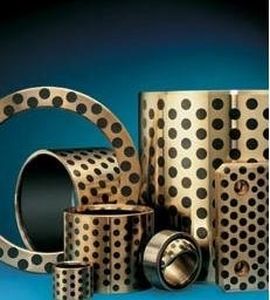

Self-lubricating plain bearing deva.glide®cylindricalbronzebrass

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Material

- bronze, brass, copper

- Other characteristics

- self-lubricating, wear-resistant

Description

deva.glide® materials consist of highly wear-resistant copper and brass alloys with sliding surfaces that are uniformly equipped with "macro-distributed" solid lubricant deposits. Depending on movement sequence, it must be ensured that the sliding plugs are adequately coated in order to build up a transfer film for a stable sliding bearing operation. The high density of the bronze guarantees a high loading capacity with a great capability for embedding any dirt particles in the lubricant depots at the same time. Two graphite-based plugs and one PTFE-based plug variant are available. In technical dry operation, deva.glide® is provided with a 10 to 20 µm thick running-in film that enables solid lubricant transfer to the counterpart material even when the sliding partners first come into contact.

A separating lubricating film is only able to form on conventional, lubricated bronze materials if suitable movement conditions and sliding speeds are present. With deva.glide®, lubrication is carried out by the sliding material itself. Even during the initial sliding movements, solid lubricant is released from the sliding material through microabrasion. This leads to the formation of smooth surfaces with a firmly adhering film of solid lubricant on the sliding partners. The lubricant remains in the contact zone even under high loads. This ensures extensive separation of the sliding surfaces and a constantly low coefficient of friction with minimal wear.

Catalogs

Related Searches

- DEVA plain bearing

- DEVA metal plain bearing

- DEVA cylindrical plain bearing

- DEVA self-lubricating plain bearing

- DEVA plastic plain bearing

- Steel plain bearing

- DEVA bronze plain bearing

- PTFE plain bearing

- Radial plain bearing

- DEVA maintenance-free plain bearing

- Wear-resistant plain bearing

- DEVA composite plain bearing

- Heavy load plain bearing

- DEVA high-performance plain bearing

- Corrosion-resistant plain bearing

- Sintered bronze plain bearing

- Linear plain bearing

- DEVA lube-free plain bearing

- DEVA stainless steel plain bearing

- Swivel plain bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.