- Robotics - Automation - Industrial IT

- Industrial Software

- Process control software

- FEELTEK Laser Technology Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Process control software solution for Industry 4.0

Add to favorites

Compare this product

Characteristics

- Function

- process control

- Applications

- for Industry 4.0

Description

Support the import of kinds of vector files and bitmap files.

Support network port, serial port data reading, can facilitate automatic production line data interfaction.

Self-developed software, support further development. Optimization for application, open interface, can be customized to requirements.

Support multi correction methods: fast and high precision correction on high precision ideal platform and free adjustment of each position focal point under the non-ideal plane, and finally achieve full format focus consistency.

Provide production line marking, visual positioning marking, automation marking, and other solutions to meet the diverse needs of the customer.

Support 3D application, support importing of STL model,self-developed model, etc. Support 3D data editing rapid realization of 3D surface marking, relief processing.

Support expansion of 3D scanning requirement, it can realize the rapid localization and reverse processing of 3D workpieces, and the rapid marking of workpieces can be realized without the workpiece model.

Standard configuration

Large field marking

Optional configuration

Platform moving line, 3D surface moving line, CCD, Projection Positioning,3D surface marking, Relief, 360°rotation marking

Catalogs

No catalogs are available for this product.

See all of FEELTEK Laser Technology Co., Ltd‘s catalogsOther FEELTEK Laser Technology Co., Ltd products

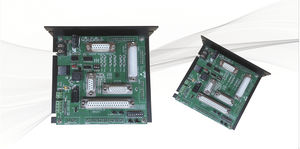

CONTROL ELECTRONICS

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.