- Machine-tools

- Machine Tool Accessory

- Electro-permanent magnetic chuck

- Femag Engineering Machinery Industry Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Electro-permanent magnetic chuck SQ FM EPMT seriesrectangularfor millingfor machining centers

Add to favorites

Compare this product

Characteristics

- Technology

- electro-permanent

- Type

- rectangular

- Applications

- for milling, for machining centers

Description

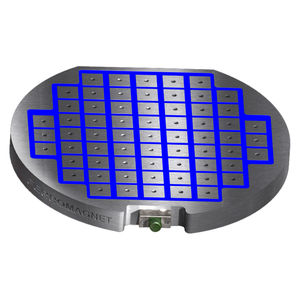

Square poles electro-permenent magnetic chuck

Type: Square pole, rectangular shape

Higher clamping force with polar winding and dual-polarity technology

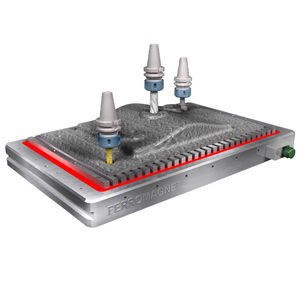

Applications: For milling, for machining centers, for machines

-Drilling

-Milling

-Slotting

-Chamfering

-Reaming

-Threading

-Broaching etc. many processes with quality results & 5-sided workpiece machining in one set-up.

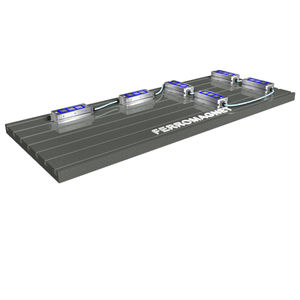

Special Design Electromagnetic Chuck as well as standards

Technology: Electro-permanent magnet (EPM)

Strong and stable magnetic force, assure tight clamping of workpiece, high processing precision

Advantages

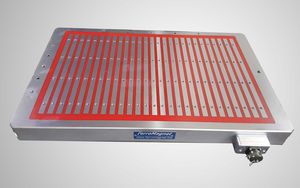

•Drastically reducing the clamping time in machining.

• No power consumes in workholding, only requires

electricity to switch on/off magnetic force.

• Very high clamping force.

• Minimum deformation and vibration clamping of the workpieces

• Increasing the cutting tools’ life.

• Practical, flexible and multifunctional.

• Special waterproof hard epoxy resin.

• Military type waterproof connector.

• Fireproof cables

• Full insulation and robust mechanics.

• Technical support before / after-sales

VIDEO

Other Femag Engineering Machinery Industry Ltd. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.