- Machine-tools

- Machine Tool Accessory

- Electro-permanent magnetic chuck

- Femag Engineering Machinery Industry Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

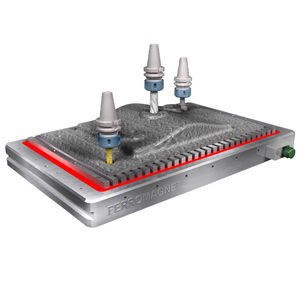

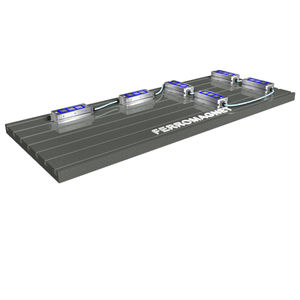

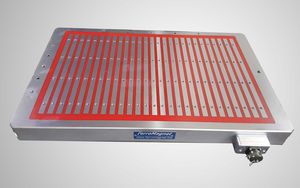

Custom magnetic chuck electro-permanentrectangularsquare

Add to favorites

Compare this product

Characteristics

- Technology

- electro-permanent

- Type

- rectangular, square

- Applications

- for machine tools

- Other characteristics

- with parallel pole pitch, custom

Description

Customized Design Electro-permanent Magnetic Chucks

Customers expectation is First

Better Quality is our Aim

Type: Parallel pole; square pole - rectangular shape (and more customized dimensions)

Technology: Electro-permanent magnet (EPM technology)

-Smart and flexible clamping solutions

-Ideal for different dimensions of workpieces

-Reasonable costs

-Attaching SLOT and attaching HOLE are designed to the electromagnetic modular systems according to customers’ preferences.

SQ & P15 & Special Design Electromagnetic Chucks

Ferromagnet has extensive technical experience in making high-quality custom-designed permanent electromagnetic chucks as well as standard electromagnetic chucks.

Applications:

- Drilling

- Milling

-Chamfering

-Slotting

-Reaming

-Threading, etc. many processes with quality results & 5-sided workpiece machining in one set-up.

Advantages :

• Using the latest technology trends in the permanent

electro-magnetic industry.

• Drastically reducing the clamping time in machining.

• No power consumes in workholding, only requires

electricity to switch on/off magnetic force.

• Very high clamping force.

• Practical, flexible and multifunctional.

•Special fireproof and waterproof cables & connectors.

• Distortion-free clamping

• Longer life of tools

VIDEO

Other Femag Engineering Machinery Industry Ltd. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.