- Products

- Catalogs

- News & Trends

- Exhibitions

(CEMS) continuous emission monitoring system machine conditionalarmgas

Add to favorites

Compare this product

Characteristics

- Type

- machine condition

- Applications

- alarm, gas, (CEMS) continuous emission, combustion

- Interface

- Modbus

- Other characteristics

- remote, data acquisition, ATEX, IP65

Description

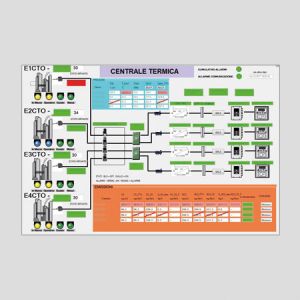

The general approach is based on the principle that adequate internal alarm systems must ensure the reliability and safety of the analysis system and that the instrumentation is not damaged. If even a single component of the system has irregular operation, which may affect its safety or accuracy, the system design ensures that the suction pump is blocked and a contact and a light signal are activated; the “alarms” and the faults of the analyzers are transmitted to the data acquisition on a remote PC.

The systems can be designed by providing the possibility to sample the gas multiplexing from different sampling points (up to 4); by means of a PLC, stainless steel solenoid valves are activated. If it is necessary not to condense the combustion product, the solenoid valves are placed in stainless steel boxes heated to 180 °C.

It is possible to realize different types of communication systems between the analysis system and the plant supervision: more commonly, by means of a complete analogical hard wired digital wiring or through local networks (LAN) with OPC standard and Modbus TCP.

A wide range of complete analysis systems can be designed, produced and put into service. All systems are designed basing on the needs of the individual customer and the features of the plant to be monitored.

Sample extraction probes with heated silicon carbide filter or steel filter. Filter cartridges with different degrees of retention are available and versions with electrical protection for ATEX zones 1 and 2. The probes can be supplied (in addition to the standard connection for the heated line) both with the backwash input and the dynamic calibration input.

Related Searches

- Environmental monitoring device

- Condition monitoring device

- Remote monitoring device

- Alarm monitoring device

- Gas monitoring device

- Data acquisition monitoring device

- Modbus monitoring device

- IP monitoring device

- IP65 monitoring device

- Machine condition monitoring device

- ATEX monitoring device

- Combustion monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.