- Materials - Tools - Components

- Hand Tool, Power Tool

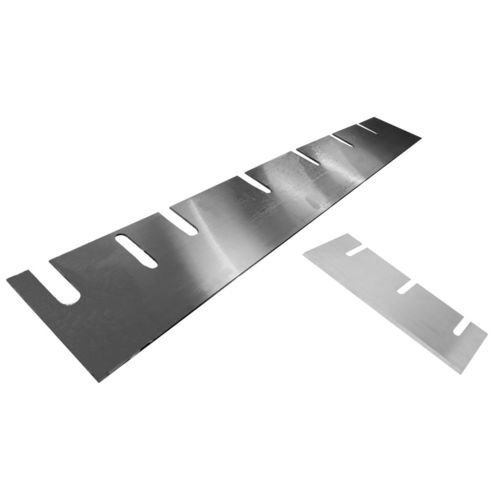

- Stainless steel saw blade

- Fernite Machine Knives

- Products

- Catalogs

- News & Trends

- Exhibitions

Stainless steel saw blade for foodcustom

Add to favorites

Compare this product

Characteristics

- Blade material

- stainless steel

- Cut material

- for food

- Other characteristics

- custom

Description

Drum dryer blades are components used in the construction of drum dryer machines in the food industry where moisture removal is essential. These blades move the material being dried as it rotates within the drum. That is why, it is crucial for these blades to have a perfectly straight edge to ensure even scraping across the surface of the drum.

Key features and functions of drum dryer blades include

Blade design: The design of the blades can vary depending on the specific application and material being dried. Blade design factors include the shape, size, and orientation of the blades, as well as their arrangement within the drum.

Material compatibility: The choice of blade material is important, as it needs to be compatible with the material being dried. Common blade materials include stainless steel or other corrosion-resistant alloys.

Maintenance: Regular maintenance of the blades is necessary to ensure the drum dryer’s continued performance. This includes inspecting for wear and tear, cleaning, and, if needed, replacing damaged blades.

Efficiency: The design and positioning of the blades impact the overall efficiency of the drying process, as well as the quality of the dried product. Correctly designed blades help prevent material clumping and ensure uniform drying.

Proper blade selection and maintenance are crucial for achieving consistent and efficient drying results in various industrial processes. Fernite Machine Knives uses only the best available steel and the latest precision grinding technology to create drum dryer blades with a consistent edge every time.

We work closely with our clients to deliver blades tailored to their specific needs,

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.