- Food industry

- Bakery-pastry

- Flaking machine

- FERRO OILTEK PVT. LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

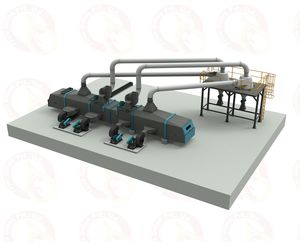

Flaking machine FF series

Add to favorites

Compare this product

Description

Flaker function by means of flaking mills, which are made by special coldrolled alloy steel. Flakers are particularly suitable for flaking oilseeds. Inorder to obtain low residual oil content in the meal after extraction, flakingis done before extracting solvents or pre-pressing.

With regard to the supply of solvent extraction plants, pressing plants forpre-pressing, full pressing, and cold pressing are required. Eligiblesuppliers in the market are identified and pressers are selected inaccordance with the raw materials and product qualities.

Most oil seeds are built of tough oil-bearing cellular structure. These mustbe shattered or weakened prior to the cooking and extraction processes.The oil seed meat is passed between smooth rolls to produce flakes of0.25 to 0.3mm. Flaking helps to activate oil cell structure and more oilextraction is available. Flaking also increases the surface area availablefor extraction of oil. Flakers are made up of one pair (two rolls), chilled,cast iron rolls mounted on a heavy duty roller bearing. In order to trapiron particles, the machine made of permanent magnetic feeder, Theequipment is provided with optimum gaps in order to adjust thearrangement (of the Hydraulic Cylinders), for maintaining the gapsbetween two rolls.

Flakers are usually used to increase the oil extraction yield at the screwpress stage or solvent extraction process. Flakers are also used toessentially reduce wear and tear.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.