- Food industry

- Bakery-pastry

- Refiner

- FERRO OILTEK PVT. LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

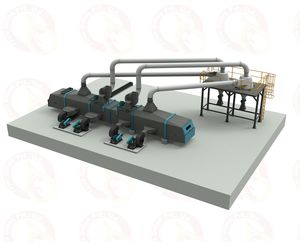

Refiner FEX series

Add to favorites

Compare this product

Description

Ferro Expanders are interrupted flight screw machines that generate a highpressure and high shear environment to perform work on a material invarious applications. An electric motor supplies the power through a gearbox or v- belt drive to rotate a shaft within a fixed and sealed tube ofcontinuous diameter.

The discharge of our Expander machine is fitted with an adjustable orificecalled a choke, which is used to control the pressure at the end of themachine and to aid in the formation of a specific round shape for the finalproduct called as Pellets/Collets.

Due to increased density and porosity created by the Expander the solventplant can see up to a 50% increase in capacity, 40% reduction in solventhold-up in the solid product and 20% reduction of solvent carry-over in theliquid product.

DESIGN FEATURES

It has equi-distant steam ports throughout the main body, helping in uniform conditioning.

Rigid and Steady body for the machine as it generates high force while pressing.

Efficient power consumption by the Expeller motor providing suitable required torque.

Reduces fines generation.

Hydraulic adiabatic attachment for oil recovery.

ADVANTAGES

The expanded product coming out of Ferro Expander can be 50% more dense than flakes

You can squeeze 50% more material into the same space allowing for dramatic increases in rates

Pellets/Collets provides maximized surface area for oil extraction for the meal

Provides highly porous structure for efficient extraction in Extractor due to easy percolation

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.