- Production Machines

- Other Manufacturing Equipment

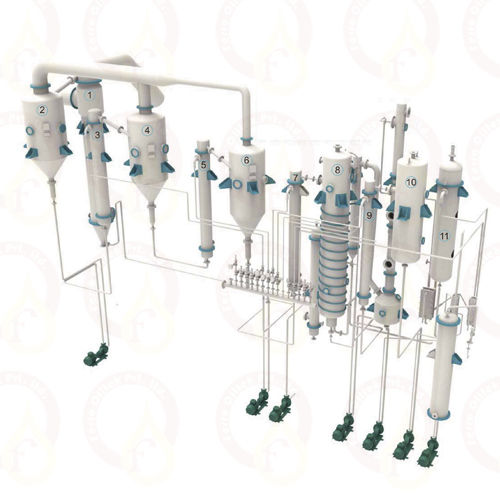

- Solvent distillation plant

- FERRO OILTEK PVT. LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

Solvent distillation plant

Add to favorites

Compare this product

Characteristics

- Options

- for solvents

Description

"Miscella" is the industrial term used for the oil/solvent mixture that leavesthe solvent extractor. The miscella leaving the solvent extractor contains70-80% solvent by weight. The purpose of distillation is to thermallyseparate the miscella into two things - a liquid oil fraction and a solventvapour fraction. Optimum use of available heat in the discharge vapourstream from the de-solventiser toaster, the available heat from thecondensate flash tank, and the heat recovery within distillation itself helpsmaximize the energy efficiency of the distillation process. The coolingtower & condenser are very important parts of distillation process.

Ferro provides a series of equipments that connected in sequence toprovide heating of miscella at a certain temperature, to make sure thehexane from the oil is vaporized and also the oil should not over heatedaffecting it's properties Ferro distillation unit collects these hexanevapours with the help of steam powered vaccum system which is highlyefficient in working and it's risk free. With Ferro Oiltek, optimum efficiencyis achieved through perfection in size and design of the distillationequipment. The miscella tank is amply sized so that it acts as a perfectbuffer after extraction to ensure the smooth flow through distillation. In ourdistillation system, we recover as much energy as possible by usingvarious heat exchangers, economizers and so on.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.