- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

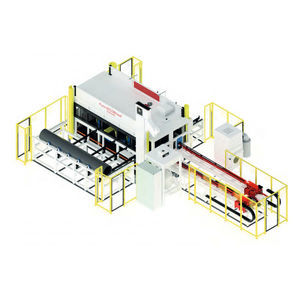

Automatic sandblasting machine Blastomatpressuresuctionrotating table

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Technology

- pressure, suction

- Other characteristics

- for surface treatment, rotating table

Description

Engineered for heavy-duty performance across diverse sectors such as foundries, plastics, and glass, the Blastomat 15-14 HD enhances surface treatment processes with its dual turntable design and advanced media recycling. This system is designed to deliver high productivity through continuous operation and meticulous control over the blasting environment.

Dual Motorized Turntables

Simultaneous loading and blasting for uninterrupted operations

-

Multiple Blasting Nozzles

Six oscillating nozzles ensure coverage across all surfaces

-

Manual Blast Nozzle for Precision

Offers manual control for detailed repairs and fine adjustments.

-

Integrated Filter and Recycling Unit

Distinguishes reusable media from waste

-

Advanced Control System

User-friendly interface for precise control over all machine parameters.

The Blastomat 15-14 HD is tailored for industries requiring robust sandblasting solutions. Featuring two motorized turntables, each with a 1000kg capacity, this machine ensures continuous operations without downtime. The setup includes six oscillating blasting nozzles that cover a comprehensive blasting area, supported by an advanced filter-recycling unit that distinguishes and reuses good media, thereby optimizing media consumption and reducing waste. Most operational parameters are easily managed via the intuitive FerroSmartPanel.

Operational Benefits

Workflows with automated dual turntables reduce cycle times and increase throughput.

Customizable blasting options allow for precise surface treatment across a variety of industrial parts.

"he robust build quality ensures durability and long-term reliability in demanding industrial environments.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Hand blast cabinet

- Robust washing machine

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.