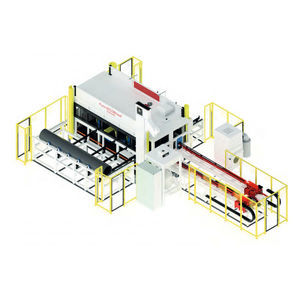

Pressure blast cabinet automatictrough conveyorcompact

Add to favorites

Compare this product

Characteristics

- Technology

- pressure

- Operational mode

- automatic

- Other characteristics

- compact, stainless steel, trough conveyor, with carousel

- Applications

- for the automotive industry, for alloy wheels, for aerospace applications, for heavy-duty applications

Description

Sandblasting of bars, tubes, and larger parts

Automatic through feed machine is used for surface preparation of bars and tubes. It is an injection type blasting system, for gentle and precise surface preparation process.

Manipulation

Precise and flexible blasting

-

Flexible Blasting Capabilities

Accommodates various part sizes and shapes

-

User-Friendly Control System

Touchscreen interfaces for easy programming and operation

-

Integrated Filter and Recycling Unit

Distinguishes reusable media from waste

-

High-Quality Construction

Durable materials and components for long-lasting performance

The machine is engineered with an automatic loading system, so it is installed directly in the production line. All parameters and processes are controlled via PLC control and can be changed on the touchscreen panel on the control box. The machine is designed to work without an operator presence for high productivity. All interior is anti-abrasive protected and easy to maintain. Media recycling system allows having repeatable surface effect, perfect operation mix for blasting and low consumption of media.

Features:

completely automized line (no operator presence)

very high production capability

heavy-duty design and protection for industrial use

PLC Touchscreen process control

easy to maintain and operate

Benefits:

no operator presence needed when dry blasting process is on

100% Repeatable process

high efficiency

low media consumption

perfect surface preparation process

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.