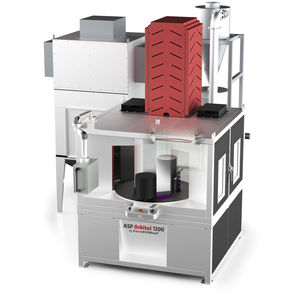

Robotic shot peening machine ARSProtating tablefor metal

Add to favorites

Compare this product

Characteristics

- Type

- rotating table

- Applications

- for metal

- Other characteristics

- robotic

Description

Our ARSP series, encompassing both automated and robotic shot peening systems, is designed to meet the rigorous requirements of industries like aerospace, automotive, and heavy machinery. These systems provide highly controlled and repeatable shot peening for critical components to enhance fatigue strength and lifespan.

High Precision

Ensures exact peening intensity for optimal results.

-

Fully Automated

Minimizes human error and increases throughput

The ARSP systems are versatile enough to handle various components such as gears, shafts, and aerospace parts. Each system is tailored to meet the specific requirements of these applications, ensuring compliance with industry standards and enhancing the structural integrity of each component.

What it is for

Aerospace Components: Enhances resistance to fatigue and stress corrosion cracking.

Automotive Parts: Increases longevity and performance of gears and shafts under extreme conditions.

Heavy Machinery: Improves wear resistance and strength of critical structural components.

Features of the ASP Series

Dual Motorized Turntables: Ensures continuous operation by allowing simultaneous loading and processing.

Robotic Manipulation (ASPR models): Offers high precision handling and peening for complex geometries, ideal for aerospace and automotive parts.

Comprehensive Media Recycling Systems: Integrated systems that filter and recycle the blasting media, reducing waste and operational costs.

Customizable Pressure Settings: Allows adjustments to be made based on the specific needs of the material and the desired finish.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.