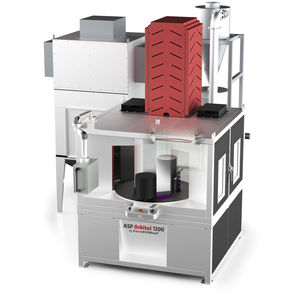

Robotic shot peening machine AR seriesrotating tablefor metal

Add to favorites

Compare this product

Characteristics

- Type

- rotating table

- Applications

- for metal

- Other characteristics

- robotic

Description

Shot peening inner and outer diameters of landing gears

This large robotic shot peening system with two separate chambers (ARSP&ARGB) is designed to peen internal and external surfaces of a range of landing gear components. The parts are loaded and manipulated using an integral machine mounted hoist connecting both chambers and can be rotated or indexed on the precise servo turntables.

Keeping in mind challenging geometries of typical landing gear components customized multiple tooling systems was developed. For smallest and most precise ID a robotic manipulated rotating lance was installed. Lance design incorporates servo mechanism always driving small lance with a stable preset value of RPM. This combining with accurate indexing table presents an ideal solution not only for landing gear ID but also for other aerospace components such as LPTs or other objects containing small sized grooves and apertures. A large automatic horizontal rotating lance is programmed to peen the ID surfaces of largest parts

Work object manipulation and system flexibility

Complete system design was performed with special care for manipulation of components between both chambers. The idea was to provide a possibility of object loading, unloading and cross transfer with little manipulation as possible and without the necessity for external crane or hoist. Both chambers are interconnected with clever manipulation transport line consisting of rails for precise guidance and positioning of two trolleys and connecting hoist for object lifting.

Special attention was given to the design of each transport trolley. Trolleys are equipped with indexing turntables and powered through flexible power lines

VIDEO

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.