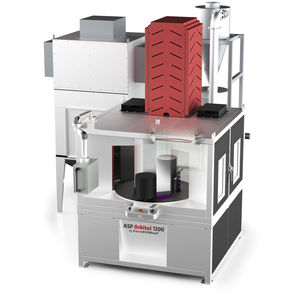

Automatic shot peening machine ASP PEENLINE 4/1000 ECOrotating tablefor metal

Add to favorites

Compare this product

Characteristics

- Type

- rotating table

- Applications

- for metal

- Other characteristics

- automatic

Description

Advanced Shot Peening Systems for Precision Surface Enhancement

The ASP Peenline System is crafted to provide a robust and precise solution for the shot peening of a variety of industrial components, improving their fatigue resistance and overall longevity. This system is particularly adept at handling complex components across aerospace, automotive, and heavy machinery sectors, ensuring uniform treatment and optimal surface condition.

High Precision

Allows for precise adjustments to peening intensity and coverage.

-

Dual Conveyor System fully Automated

Facilitates efficient loading and treatment processes.

-

Versatile Application

Suitable for a wide range of industrial parts.

This machine provides controlled and repeatable Shot Peening of various metal or alloy machined structural components with high-efficiency cut wire media, with four adjustable nozzles attacking workpieces from 4 different angles. Unlike previously mentioned solutions where workpieces are fixed on indexing turntable for high precision positioning and accurate processing, machine ASP PEENLINE 4/1000 ECO is designed as a through feed system with heavy duty transport line for workpieces manipulation.

Transport line is feeding objects into the peening cabinet in a controlled manner where travel liner speed if controlled via PLC and SCAD.

A machine is enabling workpieces manipulation in directions, these allowing operators to flip or reposition object after one side (surface) has been processed.

Special care was taken in the design of technological openings for parts exit and entrance to a cabinet in order to prevent the escape of reflected peening media.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.