Automatic shot peening machine ASP ECO seriesrotating tablefor metal

Add to favorites

Compare this product

Characteristics

- Type

- rotating table

- Applications

- for metal

- Other characteristics

- automatic

Description

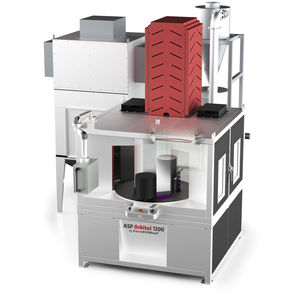

ASP automatic shot peening systems are engineered to deliver performance in surface enhancement through shot peening. These machines are suitable for treating various metal parts, providing consistent and effective peening results. The robust construction and advanced features make them ideal for industrial applications such as maintenance, repair, and surface preparation.

Durable Construction

Built with high-quality materials for long-lasting performance

-

Automated Shot Peening

Ensures precise and consistent peening results.

-

High Load Capacity

Capable of handling large and heavy workpieces

-

Integrated Filter and Recycling Unit

Distinguishes reusable media from waste

-

User-Friendly Interface

Simple and intuitive controls for ease of use

The ASP shot peening systems are designed to operate in a universal and flexible working process. They can run in fully automatic mode, ensuring consistent and repeatable results on workpieces. Customizable programs for different workpieces can be created and stored in the system’s main CPU, offering easy retrieval and execution.

Operators load workpieces onto the carriage, which is then pushed into the machine. After closing the two-wing doors, the operator starts the machine and uses the manual injector gun to direct the peening process. The abrasive media is pneumatically transported from the cabinet to the recovery unit and back into the blasting process. Dust and oxide are collected in the filter unit's hopper.

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.