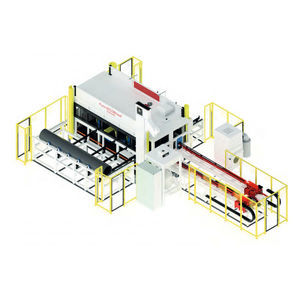

Robotic sandblasting machine Ax-Blast ECOinjectorpressureinternal

Add to favorites

Compare this product

Characteristics

- Operational mode

- robotic

- Technology

- pressure, injector

- Other characteristics

- internal

Description

Efficiently Clean Burned-on Sand, Rust, and Scale from Internal Axle Surfaces

Our internal blasting machine excels in automating the cleaning process of car and truck axles after external treatments. With user-friendly programming and a design tailored to fit specific technical requirements, this machine offers a fully automatic operation mode that guarantees uniform cleaning results. Each unit is built to accommodate future robotic loading/unloading, making it a smart choice for evolving production environments.

Heavy-duty Blasting

Wear-resistant interior designed for longevity

The AX – BLAST ECO operates through a revolving feeder system that positions axles horizontally, moving them through various internal blasting stations. This setup achieves the required cleaning efficiency within a 120-150 second cycle, optimizing your production line's throughput. Its modular design allows for easy maintenance and quick adaptation to different axle types, providing a versatile solution for automotive manufacturers.

Benefits of Internal Blasting Machine

Significantly increases the lifespan of axles by removing internal impurities.

Reduces the risk of part failure due to corrosion and material fatigue.

Enhances overall vehicle safety and reliability.

Equipped with a checking system that includes vision cameras and sensors ensuring precise part placement and verification before, during, and after the blasting process. This system guarantees that each axle is correctly aligned and meets quality standards, providing an essential layer of quality assurance and reducing the potential for defects.

Catalogs

No catalogs are available for this product.

See all of FerroECOBlast‘s catalogsRelated Searches

- Automatic washing machine

- Industrial washing machine

- Parts washing machine

- Blast room

- Sandblaster

- Pressure sandblaster

- Robust washing machine

- Hand blast cabinet

- Laser cleaning system

- Manual sandblaster

- Mobile sandblaster

- Pressure blast room

- Powder coating booth

- Automatic sandblaster

- Surface treatment sandblaster

- Injector blast cabinet

- Automatic blast room

- Injector sandblasting machine

- Blast cabinet for the automotive industry

- Wet blasting cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.