- Machine-tools

- Machining Center

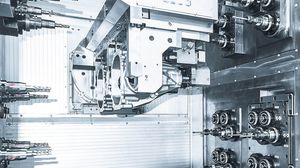

- 5-axis machining center

- FFG Europe & Americas

5-axis CNC machining center Sigma Flexiverticalwith moving tableBT 40

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with moving table

- Spindle mount

- BT 40, HSK A-63, SK40

- Number of tool stations

- 40 tools, 60 tools, 50 tools

- Applications

- for molds

- Other characteristics

- high-performance, high-precision, with automatic tool changer

- X travel

1,250 mm, 1,600 mm, 2,100 mm

(49.21 in, 62.99 in, 82.68 in)- Y travel

800 mm

(31.5 in)- Z travel

950 mm

(37.4 in)- Rotational speed

12,000 rpm, 18,000 rpm

(75,398 rad.min-1, 113,097 rad.min-1)- Power

23 kW, 30 kW

(31.27 hp, 40.79 hp)- Work feed X-axis

40 m/min, 50 m/min

- Work feed Y-axis

50 m/min

- Work feed Z-axis

50 m/min

- Table load capacity

1,500 kg, 2,000 kg, 2,500 kg

(3,307 lb, 4,409 lb, 5,512 lb)- Tool weight (max)

7 kg

(15.4 lb)- Tool-changing time

5 s

- Weight

11,000 kg, 12,500 kg, 14,000 kg

(24,250.85 lb, 27,557.78 lb, 30,864.72 lb)- Overall width

4.2 m, 4.7 m, 5.5 m

(13'09" , 15'05" , 18'00" )- Overall height

3.9 m

(12'09" )

Description

Sigma Flexi vertical machining centers have a movable work table and five simultaneously controlled axes to offer universal application options. This 5-axis machine is suitable for both small and large series of complex workpieces that have to be produced in a single setup. From machinery/ general engineering to mold and die making.

ADVANTAGES

HOW TO BENEFFIT FROM SIGMA FLEXI VERTICAL MACHINING CENTERS

The movable work table on the Sigma Flexi vertical machining center that travels along the X-axis enables top workpiece precision and quality. Precision and position repeatability is increased even further by automatic compensation for temperature drifts on the spindle and linear axes using sophisticated sensors.

Motor spindles developed in-house ensure the highest performance (33 kW), torque (235 Nm) and speed (19,000 rpm) with a long service life. The machine's structural design permits outstanding strength for extreme utilization of its spindle's power and torque.

IDEAL YIELD RATES

The tool magazines on a Sigma Flexi vertical machining center are structurally independent of machine movements. This enables tools on the chain to be easily and safely checked and replaced without interrupting the machining cycle.

SAFE TOOL CHANGING

Sigma Tool Check, an electronic device near the tool loading and unloading system, permits the tool magazine and tools to be fetched, assigned and managed. Direct connection with the CNC controls ensures uninterrupted machining cycles.

APPLICATIONS

TOP PERFORMANCE FOR MAXIMUM PRECISION

Five CNC functions on Sigma Flexi vertical machining centers enable dynamic configuration during milling

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsOther FFG Europe & Americas products

MACHINING CENTERS AND CNC SYSTEMS

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.