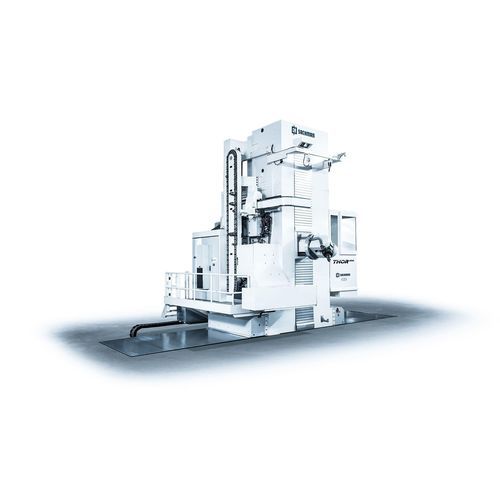

Sachman Thor 200 milling centers are specifically designed to meet the demanding requirements of contract manufacturing. The horizontal machining centers are available in 2 versions: as a high-speed milling machine for machining composites and metal, especially for aviation parts like wings and fuselage parts, and as a high-performance milling center for the precision machining of large parts for general engineering, the energy sector and large tools for the aviation industry.

ADVANTAGES

Feed along the X-axis is on guides with multiple roller shoes via a dual-drive system with electronic elimination of hysteresis. Feed along the Y-axis is on three highly rigid guides via a double dual-drive ball screw. Feed along the Z-axis is on four high-precision guides that are arranged symmetrically opposite the spindle axis.

MAXIMUM STABILITY

Sachman Thor 200 milling centers have a traveling column that has a stabilized thermo-symmetrical structure. Optimized positioning and orientation by the guides ensures maximum rigidity and compactness. The 44 kW universal or fork milling head also offers a plus for performance and rigidity.

IDEAL ERGONOMICS

Ergonomic operator stations enable machining to be monitored safely and provide direct access to the workpiece. The guides on the X-axis bed are positioned beneath floor level and have a walk-on cover that permits convenient access.

HIGH FLEXIBILITY

Sachman Thor 200 milling machines offer a chained tool magazine with 40/60 spaces.