- Machine-tools

- Machining Center

- 3-axis machining center

- FFG Europe & Americas

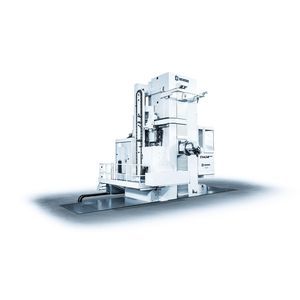

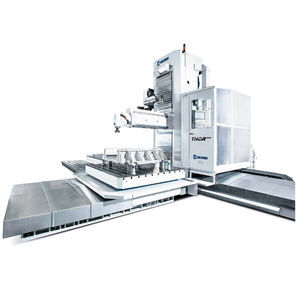

3-axis CNC milling center JOBS JOMAX series2-axisverticalgantry type

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis, 2-axis

- Spindle orientation

- vertical

- Structure

- gantry type, double-column, traveling-column

- Applications

- for large workpieces, for heavy-duty machining, for titanium

- Other characteristics

- high-precision, high-performance, high-rigidity

- Power

75 kW

(101.97 hp)

Description

Jobs Jomax are high-performance milling machines for machining on 3/3+2/4/5 axes. They are available in both horizontal and vertical versions. Jobs Jomax milling machines were especially developed for machining parts in general engineering, the energy sector and heavy mechanical engineering. Their focus is on form machining using large form holders and tools, including the intensive machining of large structural parts made of titanium. The Jomax series includes milling center models with a traveling table, a movable gantry and a traveling column.

ADVANTAGES

HOW TO BENEFIT FROM JOBS JOMAX HIGH-PERFORMANCE MILLING CENTERS

Jobs Jomax milling centers for machining on 3/3+2/4/5 axes are convincing due to their high chipping capacity (up to 75 kW) and high dynamic in acceleration and speed (up to 32 m/min).

The X/Y/Z axes on Jobs Jomax milling machines use preloaded rollers to slide on highly rigid guides. Measuring systems using linear scales with very high resolution also ensure maximum precision.

IDEAL ERGONOMICS

Ergonomic operator stations enable machining to be monitored safely and provide direct access to the workpiece. The X- and Y-axes are protected by roller shutters (accessible for the X-axis) that permit convenient access.

HIGH FLEXIBILITY

Jobs Jomax milling machines offer comprehensive configuration options like pallet systems, connections between multiple machines, tool changing systems with up to 400 tools and milling heads with an automatic changing system (BUSS) for complete machining from roughing to finishing on a single machine.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.