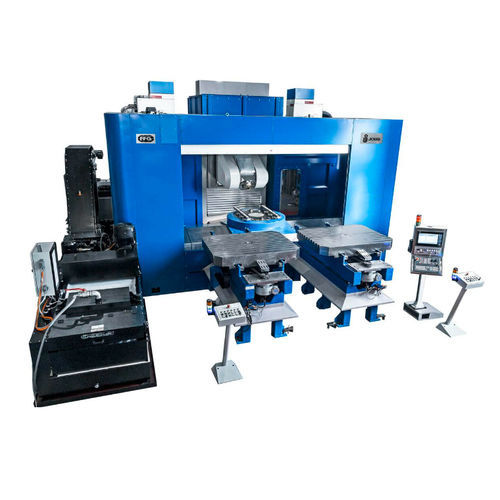

The Jobs TRT1000 is a high-performance milling machine for heavy machining and has linear roller guides on all 3 axes. This transverse-column milling center was designed as a bed milling machine and features a pallet changer for machining hard materials like titanium, amongst others in the aviation, automotive, general engineering and energy technology sectors.

ADVANTAGES

HOW TO BENEFIT FROM JOBS TRT1000 MILLING CENTERS

TOP PRECISION

Jobs TRT1000 machining centers are characterized by their column that moves on the transverse path. This addresses the problem of hydraulic asymmetry that is typical for this type of machine.

The linear roller guides permit high velocity and acceleration. The result: outstanding roughing efficiency thanks to large dimensions and slide blocks on all axes.

IDEAL EFFICIENCY

The main feature of Jobs TRT1000 milling centers is the rotary table that moves along the X-axis (pallet dimension 1,250 x 1,600 mm) with a pallet changing system and two pallet spaces in front of the machine. The milling machine can operate in oscillation mode in this configuration.

GREAT ERGONOMICS

In addition to the ability to load heavy parts, Jobs TRT1000 milling machines offer easy accessibility. The column is equipped with a tilting head.

The Jobs TRT1000 is impressive during heavy machining of medium-sized and large workpieces and hard materials like titanium. Benefit from top precision and surface quality at maximum machining speed.

Jobs TRT1000 milling machines excel in every production environment in terms of performance, efficiency and product quality. Obtain gripping insights into our machines' work environment here.