- Machine-tools

- Machining Center

- 5-axis CNC milling machine

- FFG Europe & Americas

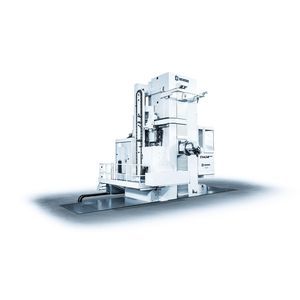

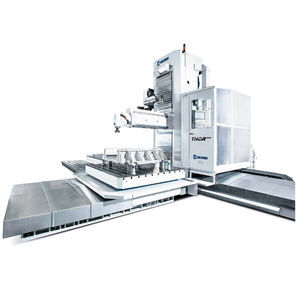

5-axis CNC milling machine RAMBAUDI RAMMATICverticalwith moving tablefor steel

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with moving table

- Machined material

- for aluminum, for steel

- Applications

- for titanium, for the aerospace industry

- Other characteristics

- high-precision, high-performance

Description

Rambaudi Rammatic 5-axis milling centers with a swivel head were specifically developed for machining contours on aluminum, steel and titanium alloy parts for the aviation industry. All Rambaudi Rammatic milling machines use a traveling column moving along the transverse axis and a movable table moving along the longitudinal axis (T-structure). This structure ensures high chipping capacity and geometric precision, regardless of the position on the transverse axis.

ADVANTAGES

HOW TO BENEFIT FROM RAMBAUDI RAMMATIC HIGH-PERFORMANCE MILLING CENTERS

The ample structures on Rambaudi Rammatic milling centers and prism-shaped guides with slide pads and rollers dampen even the strongest vibrations and provide maximum dynamic performance and chipping capacity.

All axes on Rambaudi Rammatic milling centers are equipped with direct converters. This ensures consistently high precision in machining.

IDEAL RIGIDITY

The central element of the Rambaudi Rammatic milling machine is the bi-rotary DTH spindle head with maximum rigidity. The two movements on the rotary axes occur via double-pinion racks that ensure automatic compensation for any play.

HIGH FLEXIBILITY

Rambaudi Rammatic milling centers can be equipped with a tool magazine with changer arm, workpiece and tool measuring systems, spindle heads with multiple spindles, fork spindle heads, a rotary table (6 axes) and a pallet changing system.

APPLICATIONS

Rambaudi Rammatic high-performance milling centers with a swivel head are perfectly suited to machining contours on challenging parts made of aluminum, steel and titanium alloys.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.