- Machine-tools

- Machining Center

- 3-axis machining center

- FFG Europe & Americas

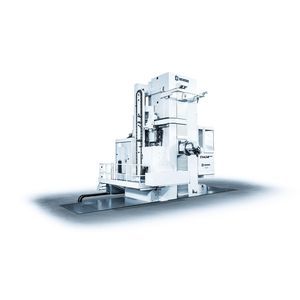

3-axis CNC milling center SACHMAN THOR 100horizontaltraveling-columnhigh-precision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Structure

- traveling-column

- Other characteristics

- high-precision, high-performance, high-speed

Description

Sachman Thor 100 milling centers are specifically designed to meet the demanding requirements of contract manufacturing. These horizontal milling machines are ideal for high-performance and high-speed machining operations in sectors like general engineering and energy, as well as for medium-sized and large tools.

DVANTAGES

HOW TO BENEFFIT FROM SACHMAN THOR 100 MACHINING CENTERS

Feed along the X-axis is on guides with multiple roller shoes via a dual-drive system with electronic elimination of backlash. Feed along the Y-axis is on three highly rigid guides via a double dual-drive ball screw. Feed along the Z-axis is on four high-precision guides that are arranged symmetrically opposite the spindle axis.

MAXIMUM STABILITY

Sachman Thor 100 milling centers have a traveling column that has a stabilized thermo-symmetrical structure. Optimized positioning and orientation by the guides ensures maximum rigidity and compactness. The universal 44 kW milling head also offers a plus for rigidity.

IDEAL EFFICIENCY

Positioning by the preloaded ball screw ensures maximum performance with minimum space requirements. The optimized machine layout on the Sachman Thor 100 milling center provides ideal ergonomics and low foundation costs.

HIGH FLEXIBILITY

Sachman Thor 100 milling machines offer a chained tool magazine with 40/60 spaces. Comprehensive equipment options like different milling heads for top performance and maximum speed and an automatic head-change system (BUSS option) permit milling solutions for every requirement.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.