- Machine-tools

- Machining Center

- 3-axis CNC milling machine

- FFG Europe & Americas

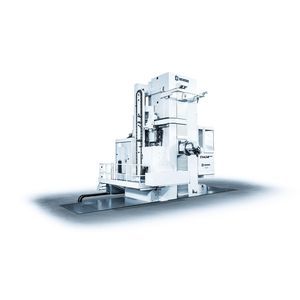

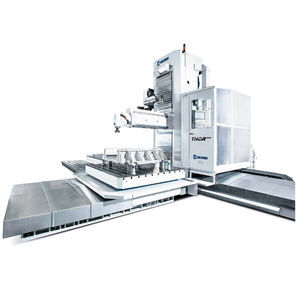

3-axis CNC milling machine SACHMAN TRT10universalhorizontalwith moving table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- universal, horizontal

- Structure

- with moving table, traveling-column

- Spindle mount

- ISO 50, HSK-A 100

- Number of tool stations

- 24 tools, 40 tools, 60 tools, 120 tools, 48 tools, 80 tools

- Applications

- for heavy loads, for crankshafts

- Other characteristics

- high-speed, high-precision

- X travel

2,000 mm, 2,500 mm, 3,000 mm

(78.74 in, 98.43 in, 118.11 in)- Y travel

1,210 mm

(47.64 in)- Z travel

1,200 mm

(47.24 in)- Rotational speed

4,000 rpm, 5,000 rpm, 6,000 rpm

(25,133 rad.min-1, 31,416 rad.min-1, 37,699 rad.min-1)- Power

35 kW, 47 kW

(47.59 hp, 63.9 hp)- Work feed X-axis

25 m/min

- Work feed Y-axis

25 m/min

- Work feed Z-axis

25 m/min

- Table load capacity

15 t

(17 us ton)

Description

Sachman TRT10 bed milling machines differ from other bed milling machines of the same size: all axis movements occur via very large roller shoes to enable high speed and/or acceleration. At the same time, however, they also feature an excellent chipping capacity. The transverse motion (Y-axis) is performed via a traveling column, whereas the longitudinal motion (X-axis) is as usual via the movable table.

ADVANTAGES

HOW TO BENEFIT FROM SACHMAN TRT10 UNIVERSAL MILLING MACHINES

HIGH STABILITY

The extremely sturdy rotary offset table is manufactured in-house and can be loaded with up to 15 tons in rotary motion. The Sachman TRT10 additionally consists completely of cast parts (X-bed, Y-bed, rotary offset table, column, head carrier, head).

The KOSMO head on the Sachman TRT10 is fully cooled and lubricated using oil, which guarantees a maximum continuous speed of 4,000 rpm for 24 hours per day and 5,000 machining cycles.

Double Hirth serrations on the TRT10 provide an accuracy of 0.02° in A and B and thus ensure greater rigidity for the head.

IDEAL CHIP REMOVAL

Three chip conveyors (two screw conveyors and a conveyor belt) provide the TRT10 with ideal chip removal.

EASY LOADING

Despite its compactness and full protective enclosure, the TRT10 offers excellent access via the front and rear to enable easy loading.

Sachman TRT10 universal milling centers can be equipped with indexed milling heads. Benefit from top precision and surface quality at maximum machining speed for all milling solutions.

Sachman TRT10 universal milling centers excel in every production environment in terms of performance, efficiency and product quality.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- 5-axis CNC machining center

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-precision turning center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.