- Machine-tools

- Machining Center

- 3-axis machining center

- FFG Europe & Americas

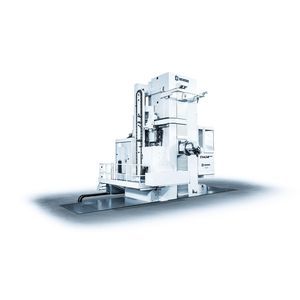

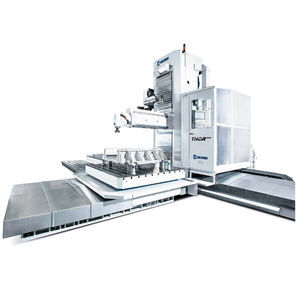

3-axis CNC milling center JOBS EVER 1 AND JOBS EVER 55-axis4-axisvertical

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis, 5-axis, 4-axis

- Spindle orientation

- vertical

- Structure

- gantry, double-column, with moving table

- Spindle mount

- HSK A-63, HSK-A 100, ISO 50

- Number of tool stations

- 40 tools, 20 tools, 60 tools

- Other characteristics

- high-performance

- X travel

4,000 mm, 5,000 mm, 6,000 mm, 7,000 mm, 8,500 mm

(157.48 in, 196.85 in, 236.22 in, 275.59 in, 334.65 in)- Y travel

3,000 mm, 3,500 mm, 4,000 mm, 5,000 mm

(118.11 in, 137.8 in, 157.48 in, 196.85 in)- Z travel

1,250 mm, 1,500 mm, 1,750 mm

(49.21 in, 59.06 in, 68.9 in)- Work feed X-axis

32,000 mm/min

(21 in/s)- Work feed Y-axis

50,000 mm/min

(33 in/s)- Work feed Z-axis

50,000 m/min

- Table load capacity

Max.: 20,000 kg

(44,092 lb)Min.: 7,000 kg

(15,432 lb)- Tool weight (max)

25 kg

(55.1 lb)

Description

Jobs Ever 5 milling centers with a movable gantry and X-axis guides beneath floor level offer high chipping capacity. Jobs Ever 1 milling centers with a fixed gantry and movable table offer maximum operator ergonomics.

Jobs Ever 1 and Ever 5 milling centers reduce hourly and operating costs, simplify maintenance and offer a high degree of application flexibility. This makes them ideal for job shops seeking cutting-edge technology at low costs.

ADVANTAGES

HOW TO BENEFIT FROM JOBS EVER MILLING CENTERS

The MT frame on Jobs Ever 1 and Ever 5 milling machines has a crossbeam that ensures high rigidity and dynamic in multi-triangle cutting. The innovative mechanics and kinematics with dual-drive on all axes enables high acceleration and speed.

TOP EFFICIENCY

Jobs Ever 1 and Ever 5 high-performance milling machines are characterized by low hourly and operating costs. Maintenance costs are also significantly reduced thanks to 35% fewer machine parts.

FLEXIBLE USE

The automatic head-change system (BUSS option) accepts a wide selection of universal milling heads, mechanically driven continuous fork heads or motor spindles for high-speed semi-finishing and finishing.

IDEAL ERGONOMICS

The ergonomic design of Jobs Ever 1 and Ever 5 milling centers ensures easy equipping. Particular attention was also paid to eco-friendliness. So their compact design enables ideal protective enclosure to efficiently retain chips and other machining residues.

Jobs Ever 1 and Ever 5 milling centers are particularly used in general engineering and the automotive industry for a huge range of product and workpiece applications.

Catalogs

EVER

8 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

- Bridge CNC milling machine

- CNC machining center with pallet changer

- Precision CNC milling machine

- Horizontal CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.